Project idea & challenge

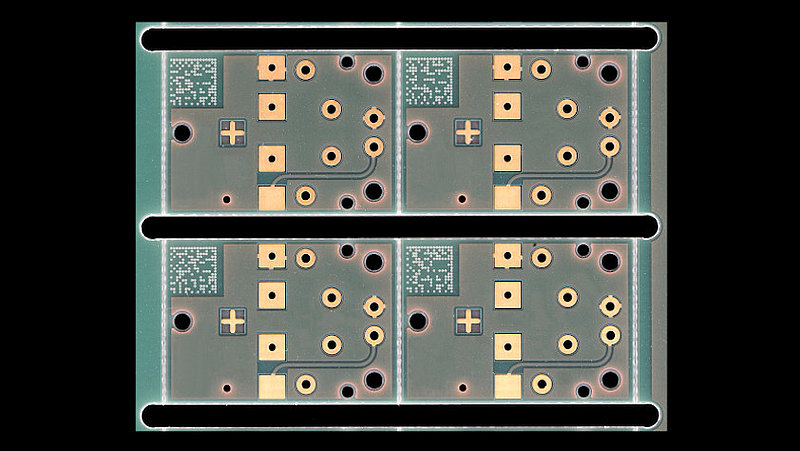

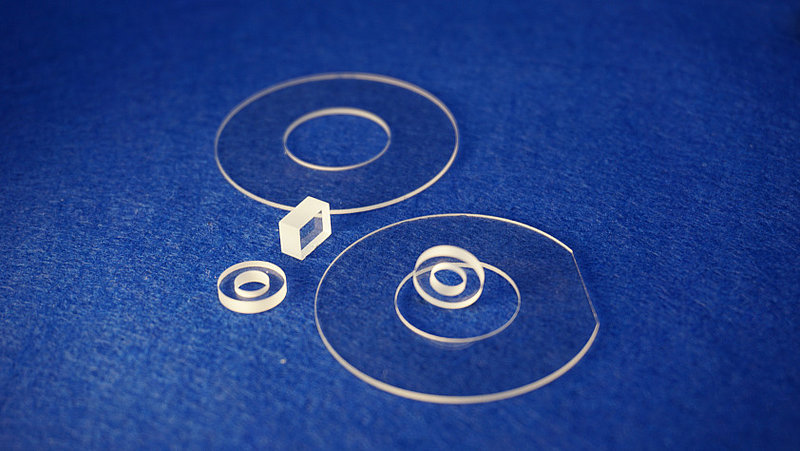

Together with LCP Laser-Cut-Processing GmbH, Fraunhofer IKTS has advanced the process development of various laser technologies for the machining, functionalisation and fabrication of technical ceramics as part of the ZIM project "PeLaKer".

This project is about laser-based processing methods for ceramic components made of the innovative material NA-ß-Aluminat. These are to be used as the centrepiece in the energy storage systems of the future.

Development goals of the project:

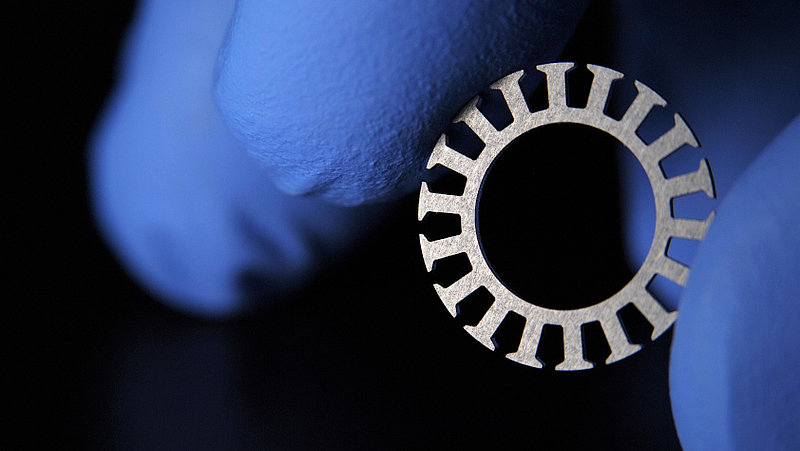

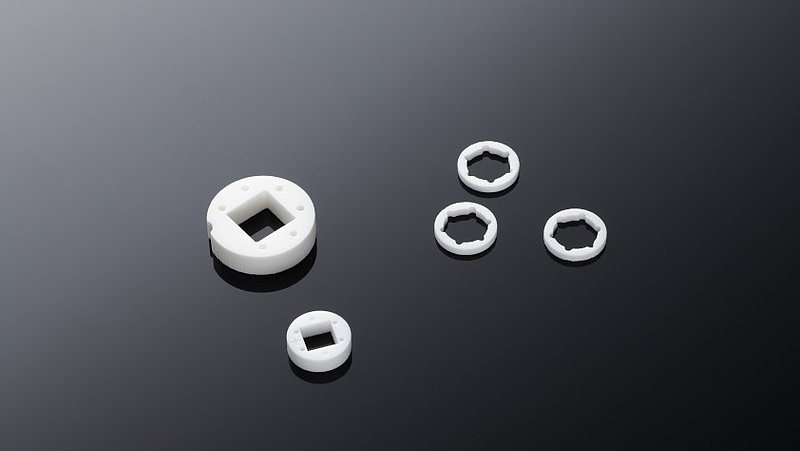

- Separation tasks

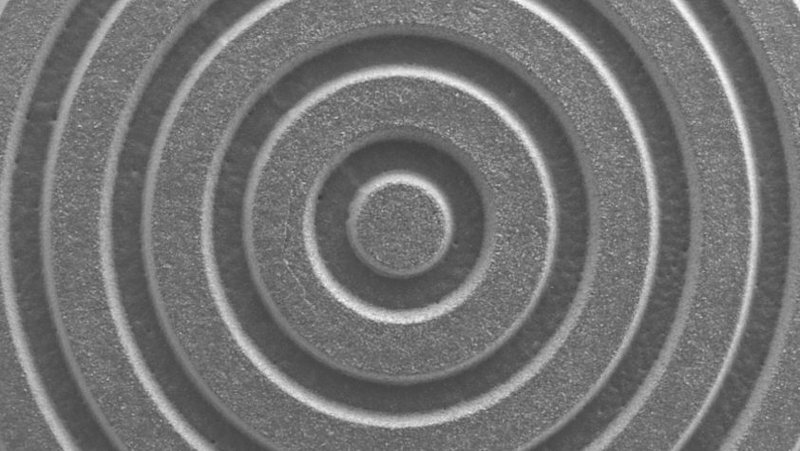

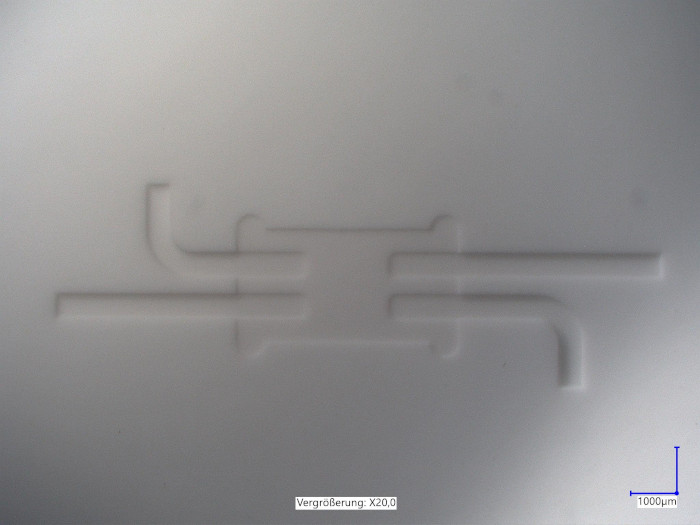

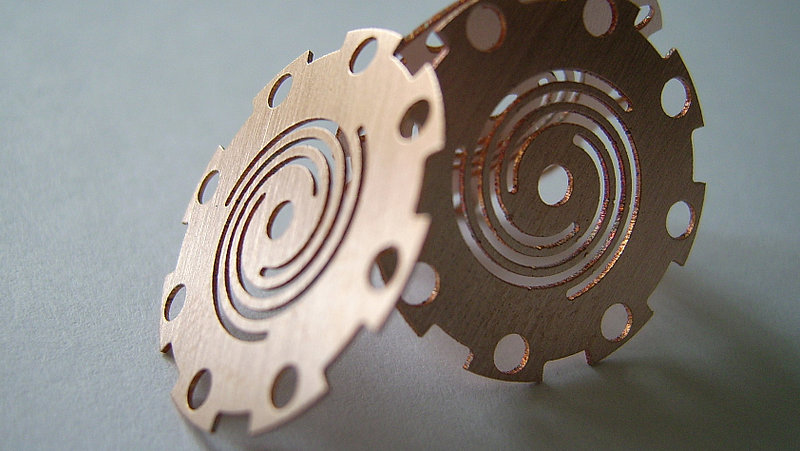

- Functionalisation of the surface

- Free-form processing / fabrication of Na-ß-aluminate ceramics

The special challenge of the project is the extreme sensitivity of the material to moisture. Even prolonged storage in normal humidity makes it unusable for final use in the battery. The laser shall be a tool that enables dry, contact-free and flexible processing and eliminates the need for costly subsequent drying processes.

Results

Main application

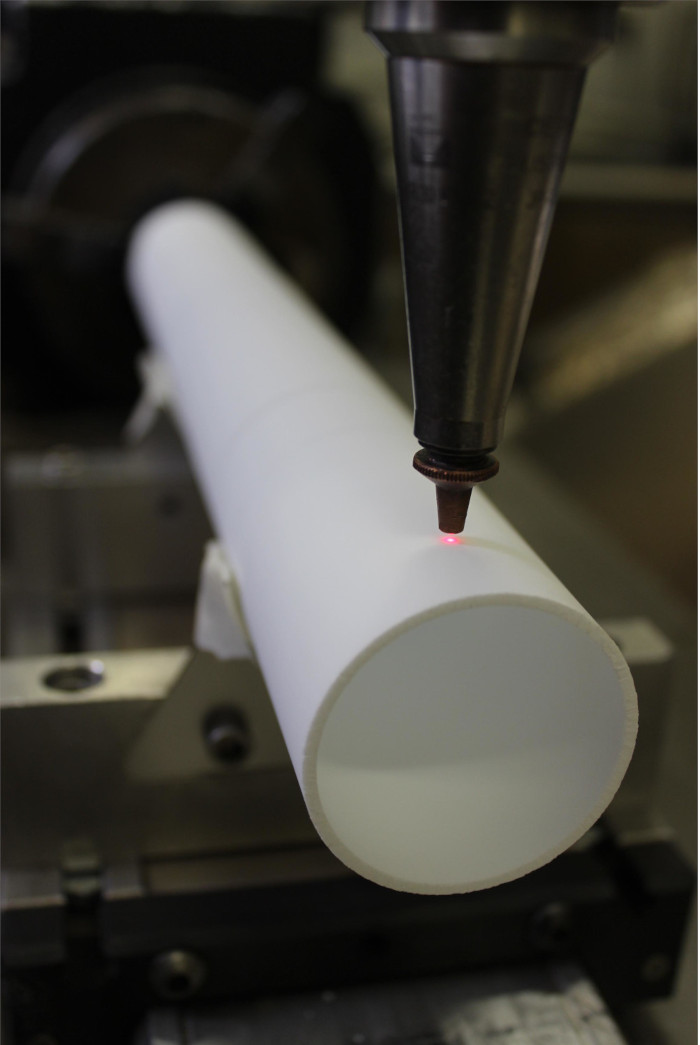

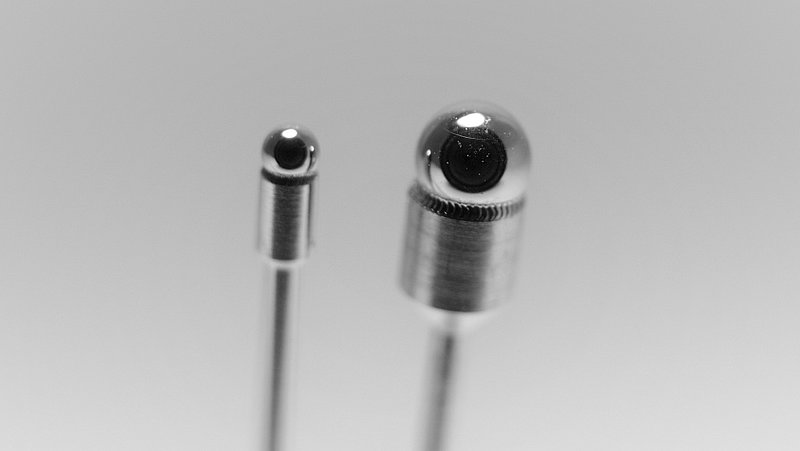

The laser tool is used to cut off the end pieces of the extruded ceramic tubes. These are closed and have a deformation at the base. The base and the deformation are cut off by laser.

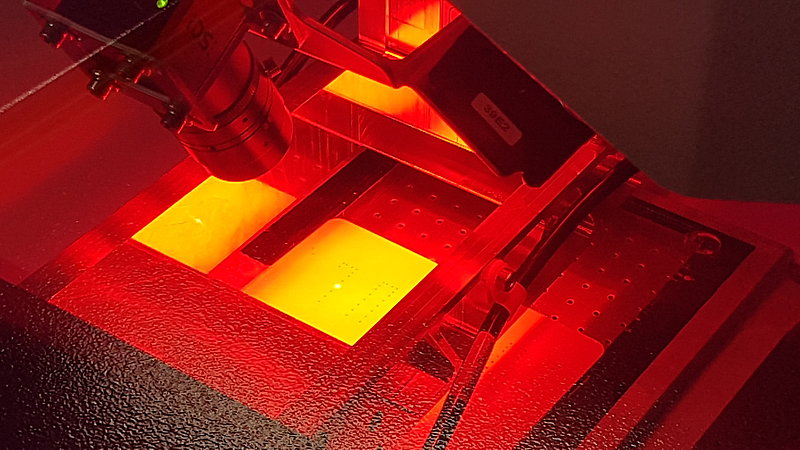

Use of technology and optimisation

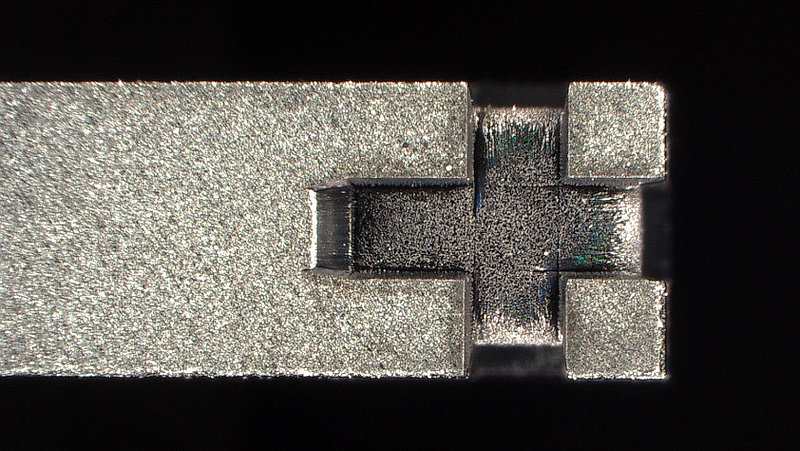

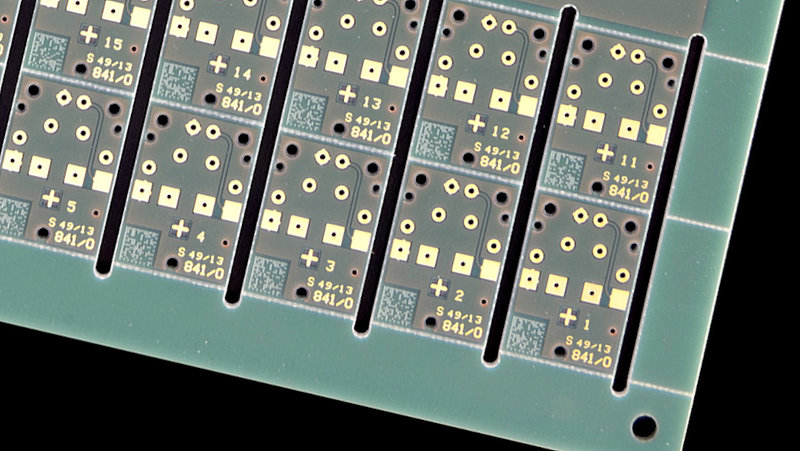

In the course of the project, laser systems with gas-assisted fixed optics as well as tilting mirror systems were used in addition to different wavelengths and power classes. Especially for the functionalisation of the surfaces

and microstructuring, the technological advantages of ultra-short pulse laser technology could be used extensively. Here, the goal of optimal processing quality, without cracks, burrs or fusion throw-up, was always in the foreground.

In addition to successfully demonstrating the feasibility of the required project tasks, the optimisation of process steps and the evaluation of automation concepts also paved the way for industrial use in a cost-effective laser technology

for industrial use in cost-effective series production.

![[Translate to English:] LCP's sporting commitment to handball](/fileadmin/_processed_/5/7/csm_handball_engagement_842x474_a29dbbab0e.jpg)

![[Translate to English:] Summer tour: Wolfgang Tiefensee visits LCP](/fileadmin/_processed_/f/7/csm_Besuch_Tiefensee_2022_Balkon_842_3ce801ac88.jpg)

![[Translate to English:] Silizium Wafer](/fileadmin/_processed_/4/5/csm_silizium_wafer_842_022e209b94.jpg)

![[Translate to English:] USP-SLS](/fileadmin/_processed_/6/0/csm_UKP-SLS_905ac12200.jpg)