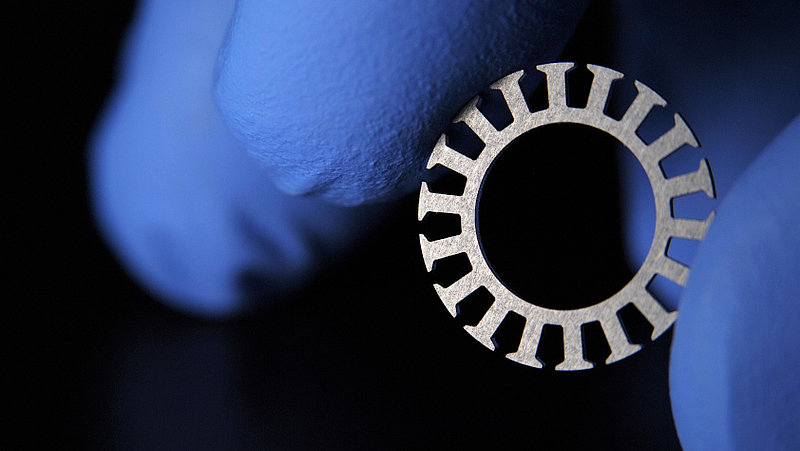

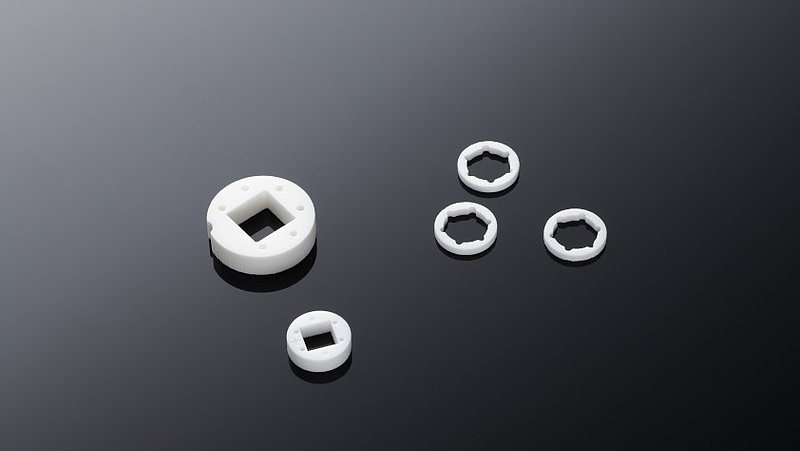

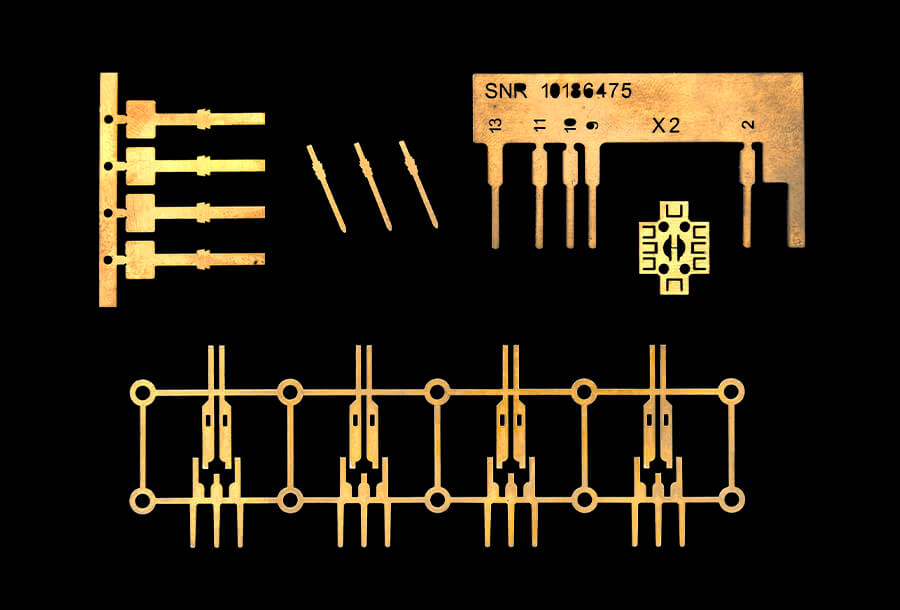

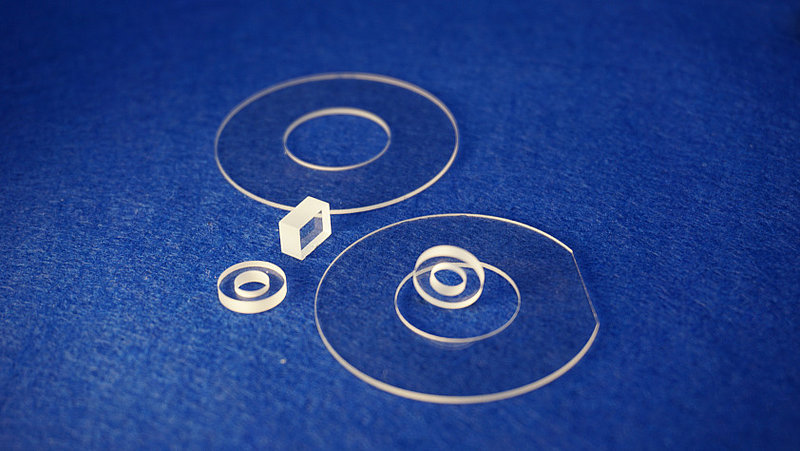

In precision mechanics, the finest mechanical components are built into devices. These components are usually quite small. The smaller a component and the more sensitive the material, the greater the challenge of producing it in accordance with the high-quality requirements.

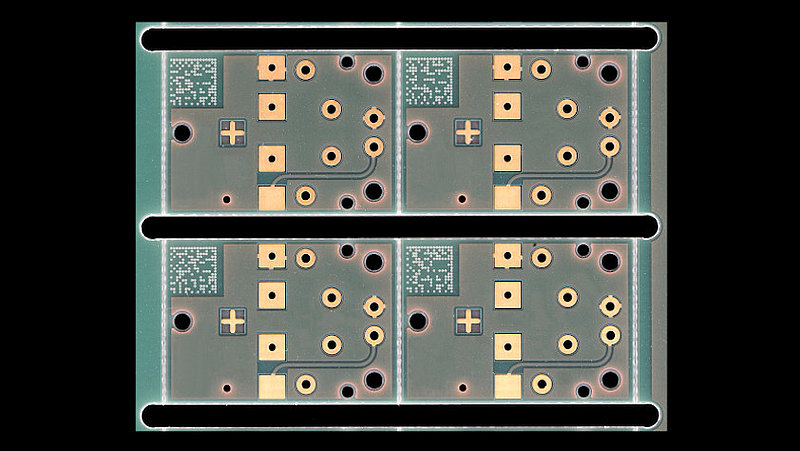

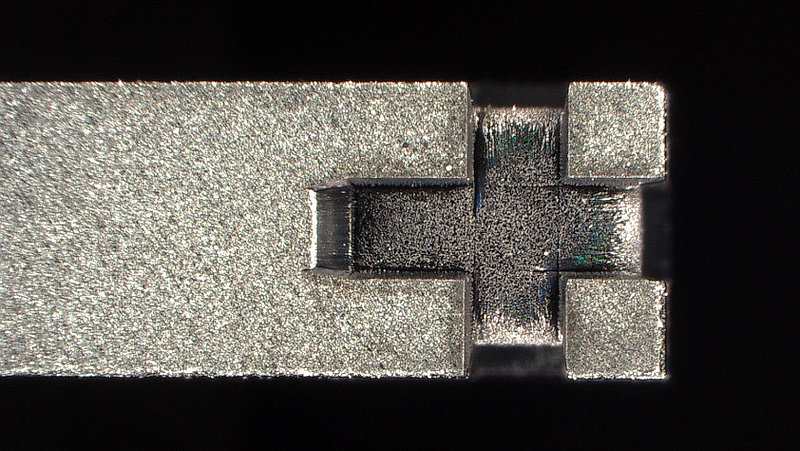

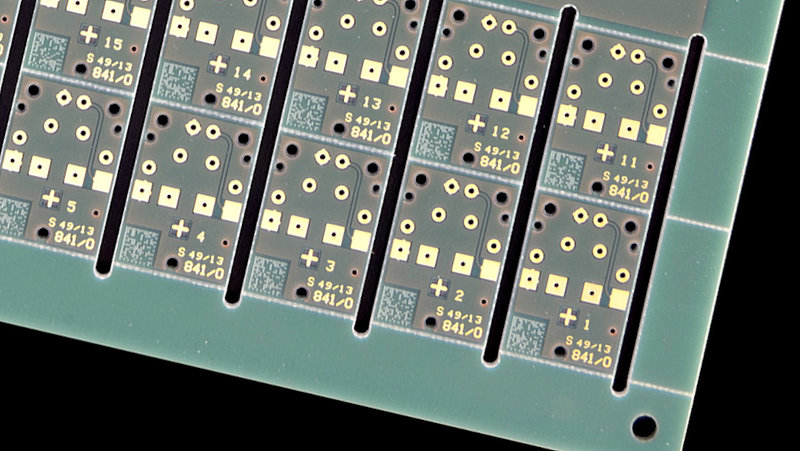

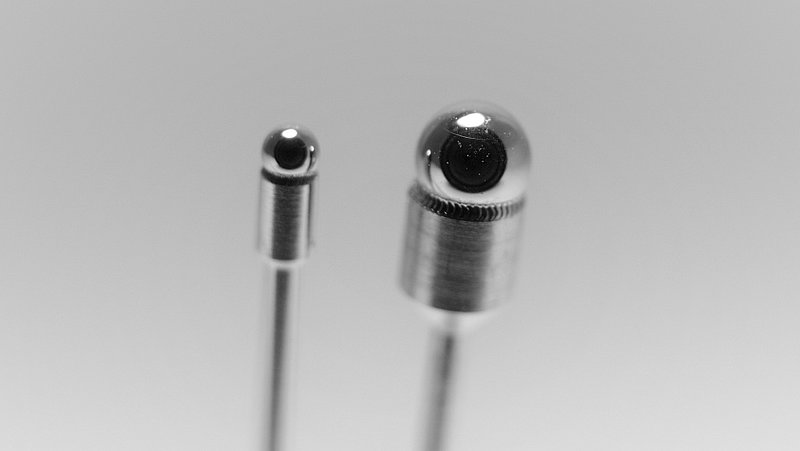

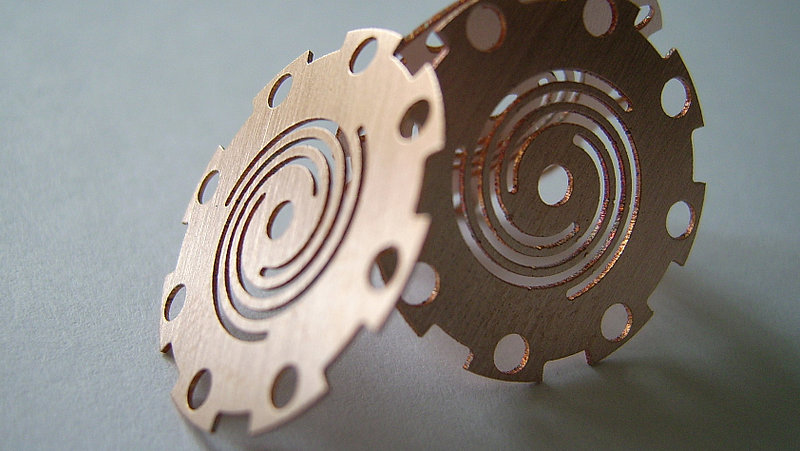

Precision mechanics plays a particularly important role in the optical industry. Here, special devices such as microscopes, binoculars and telescopes are manufactured, which are indispensable for the medical technology, research and development, electronics and aerospace industries, among others, and require highly accurate parts and components. This in turn requires super-precise manufacturing and machining of the mechanical parts with particularly high accuracy and cleanliness at the cutting and drilling edges.

This is where many years of know-how and the right technology are needed. LCP Laser-Cut-Processing GmbH, as the laser competence center for material processing of special materials and a long-standing experience leader in the field of application, manufactures individual, sophisticated and high precise drawing parts for precision mechanical components and assemblies exactly to measure thanks to the most innovative processing technologies (laser-based and mechanical). The corresponding post-control and rework is also on a high-quality level.

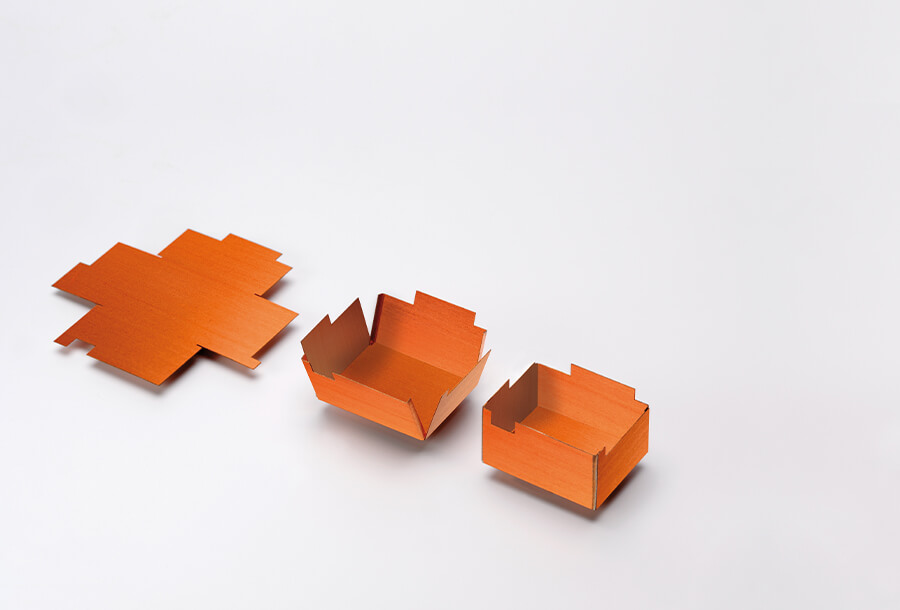

Only recently, we put a new machine for reworking into operation. This is particularly specialized in deburring and edge rounding of especially small and flat sheet metal parts from 10 to 200 mm wide and a minimum component thickness of 0.5 mm. In addition, the surfaces are given a uniform finish. The control of the machine runs completely digitally. A return conveyor ensures time-optimized work. The system also includes a suitable wet separator. Thanks to this investment in the expansion of the machine park, we can now meet and implement an even higher quality demand of our customers.

LCP accompanies its customers along the entire process chain: from consulting to prototyping to series production.

Contact us!

Further information can be found in the precision mechanics & apparatus engineering section.

![[Translate to English:] LCP's sporting commitment to handball](/fileadmin/_processed_/5/7/csm_handball_engagement_842x474_a29dbbab0e.jpg)

![[Translate to English:] Summer tour: Wolfgang Tiefensee visits LCP](/fileadmin/_processed_/f/7/csm_Besuch_Tiefensee_2022_Balkon_842_3ce801ac88.jpg)

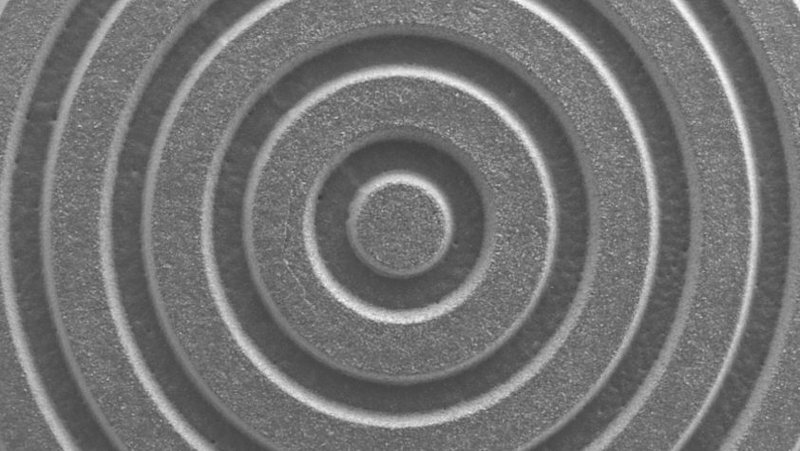

![[Translate to English:] Silizium Wafer](/fileadmin/_processed_/4/5/csm_silizium_wafer_842_022e209b94.jpg)

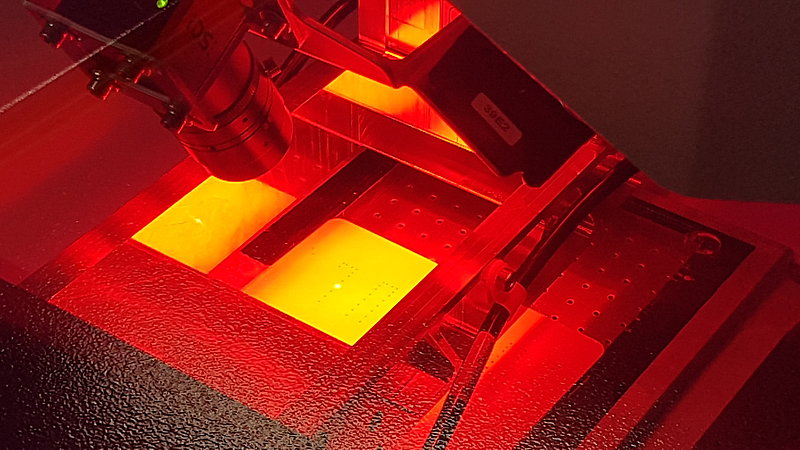

![[Translate to English:] USP-SLS](/fileadmin/_processed_/6/0/csm_UKP-SLS_905ac12200.jpg)