In cooperation with the Erns- Abbe-University of Applied Sciences Jena, the research project "USP-SLS Ceramics" started in November 2021, as part of the "Central Innovation Program for SMEs" (ZIM) of the German Federal Ministry for Economic Affairs and Energy.

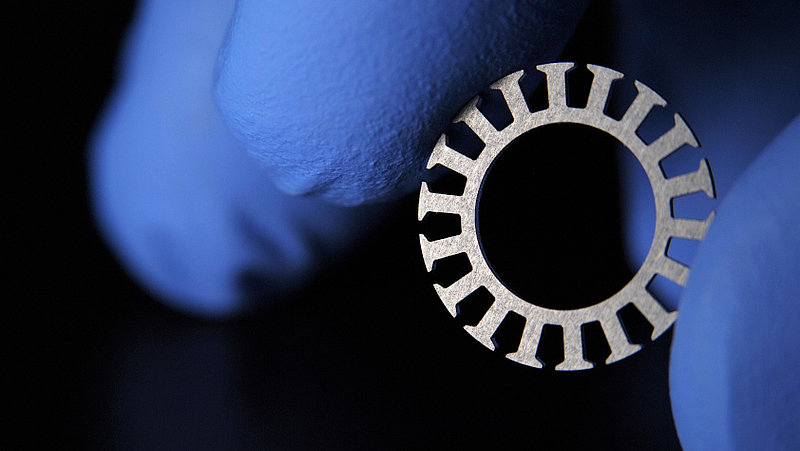

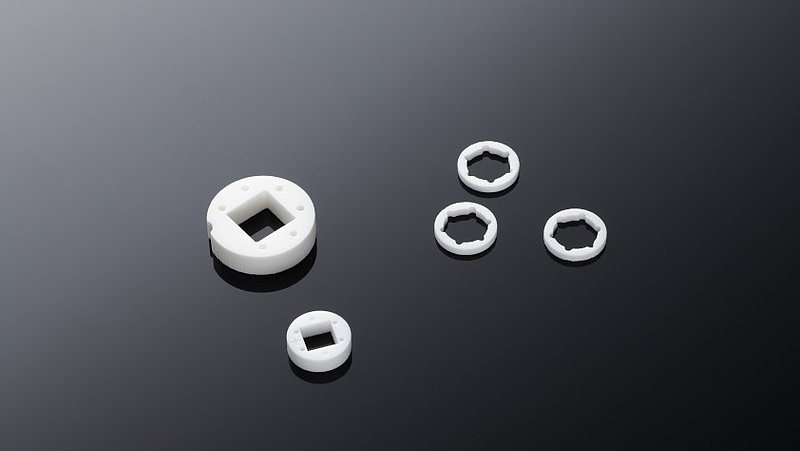

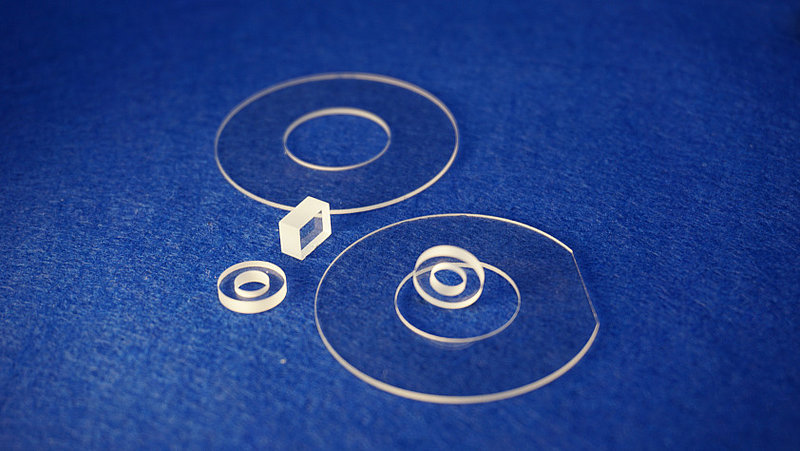

The aim of this cooperation is to develop an additive manufacturing process in which high-density ceramic functional components can be produced from ceramic powder materials without additives, using ultra-short pulsed laser radiation. Particular attention is paid here to ensuring that:

- the additively manufactured components correspond as closely as possible to the desired final contour,

- have a component density of >90% and

- do not require any post-processing.

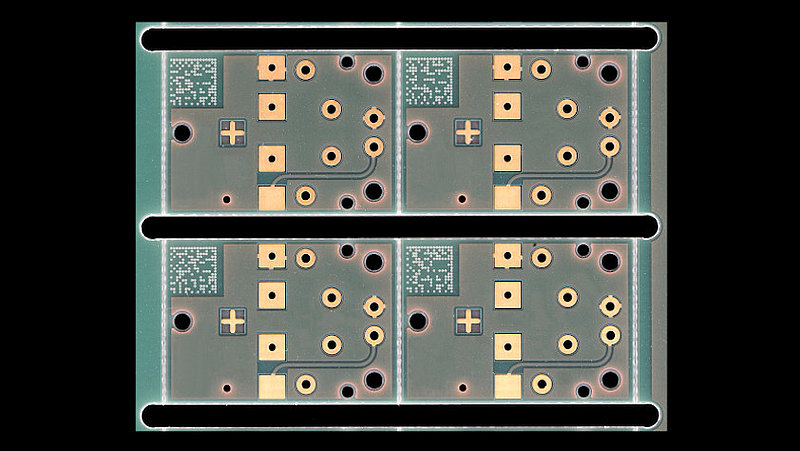

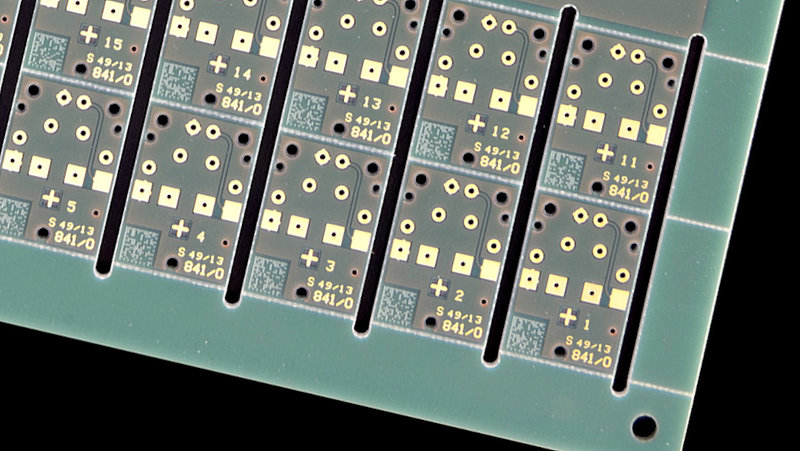

To this end, on the one hand, ceramic powder materials are being developed and investigated with regard to their process suitability, in order to bring about an increase in powder bed density and homogeneity. In particular, the oxide ceramic powders zirconium oxide powder (ZrO2) and aluminum oxide (Al2O3) are considered in the project. Mixed ceramic components are to be produced from these by additive manufacturing.

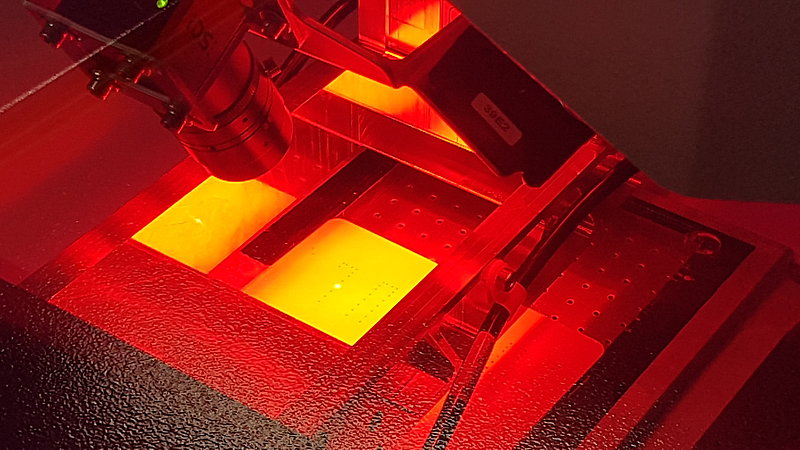

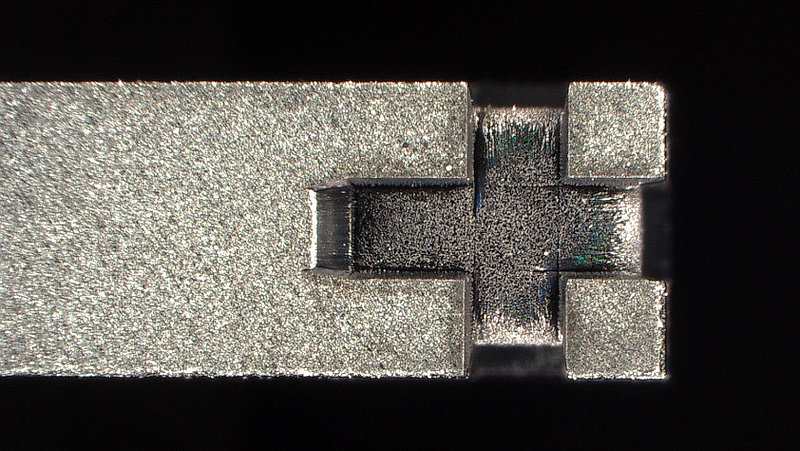

Furthermore, this research project will focus on the development of a new modular SLS (selective laser beam sintering) system technology for USP (ultrashort pulse) laser material processing equipment. This will enable the additive manufacturing of hybrid components, where complex structures are added to a conventionally machined workpiece, through the UPS-SLS.

The following project goals are to be achieved within a time frame of two years:

- development of scientific and technological fundamentals

- technical implementation of the highly innovative process chain

- verification of the process for generating high-density ceramic functional components by means of suitable demonstrators.

Sounds exciting? Then listen now to the recently published podcast with the research partners!

Research associate Anne-Marie Layer from the Ernst Abbe University of Applied Sciences Jena and Daniel Störzner, Managing Director of LCP Laser-Cut-Processing GmbH provide detailed insights into the project.

Note: The Podcast is just available in German.

Folge 40 - Keramik-Bauteile drucken – ohne Sinterofen - Druckwelle – ingenieur.de-Podcast zur Additiven Fertigung (podigee.io)

![[Translate to English:] LCP's sporting commitment to handball](/fileadmin/_processed_/5/7/csm_handball_engagement_842x474_a29dbbab0e.jpg)

![[Translate to English:] Summer tour: Wolfgang Tiefensee visits LCP](/fileadmin/_processed_/f/7/csm_Besuch_Tiefensee_2022_Balkon_842_3ce801ac88.jpg)

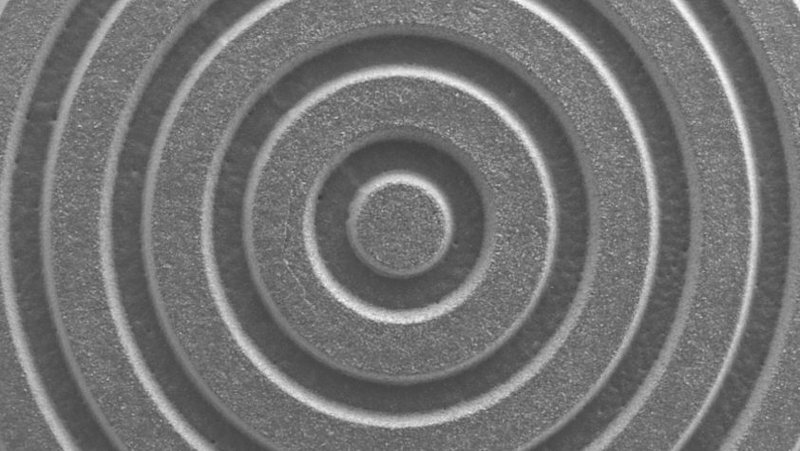

![[Translate to English:] Silizium Wafer](/fileadmin/_processed_/4/5/csm_silizium_wafer_842_022e209b94.jpg)

![[Translate to English:] USP-SLS](/fileadmin/_processed_/6/0/csm_UKP-SLS_905ac12200.jpg)