Finest components for power electronics

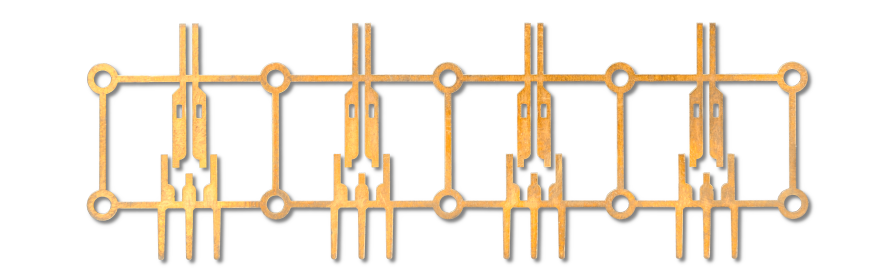

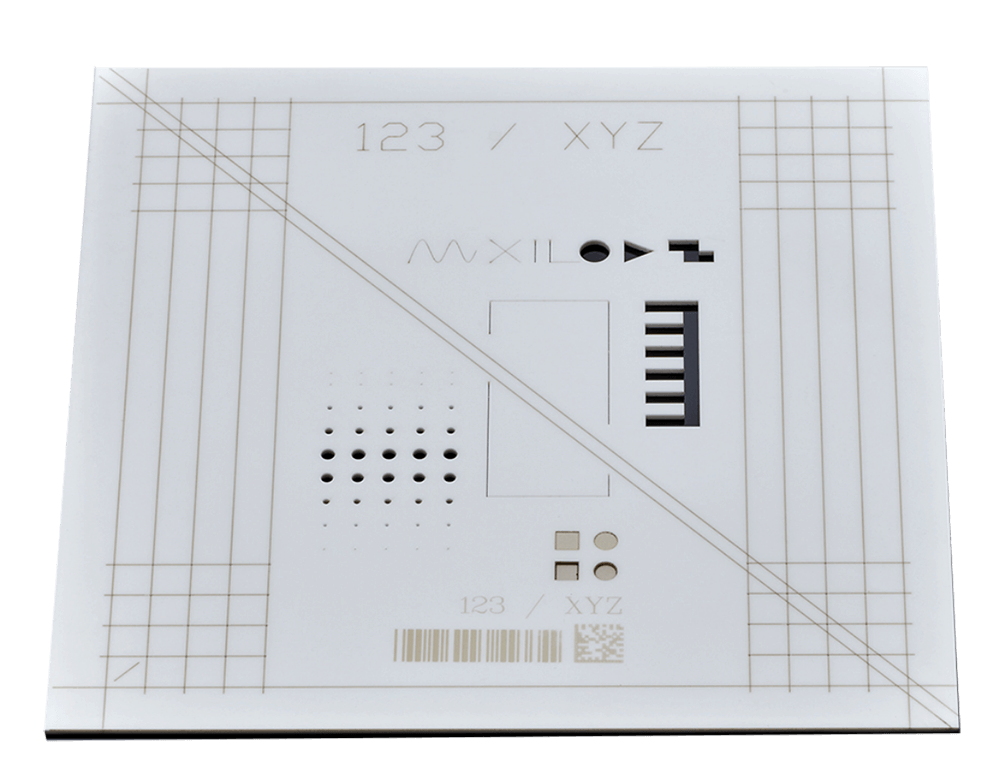

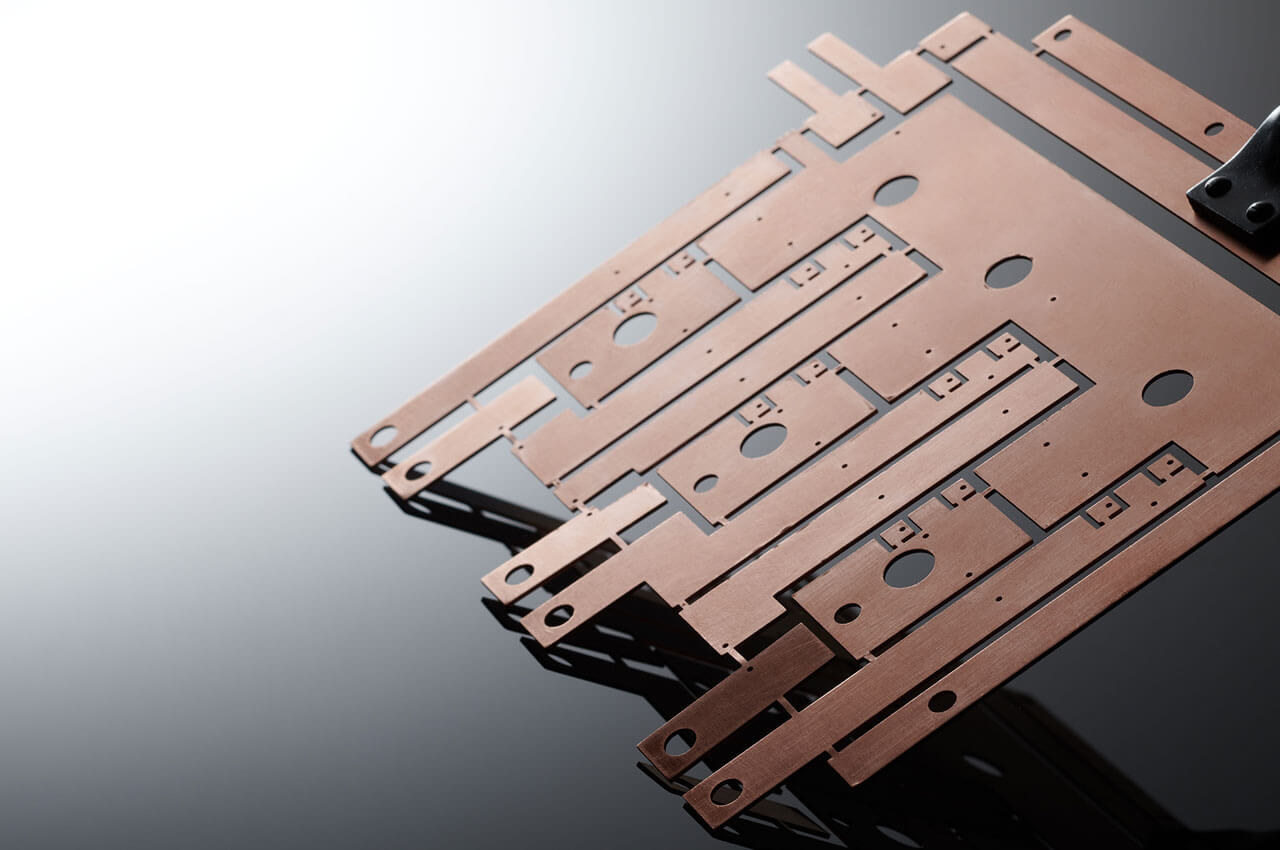

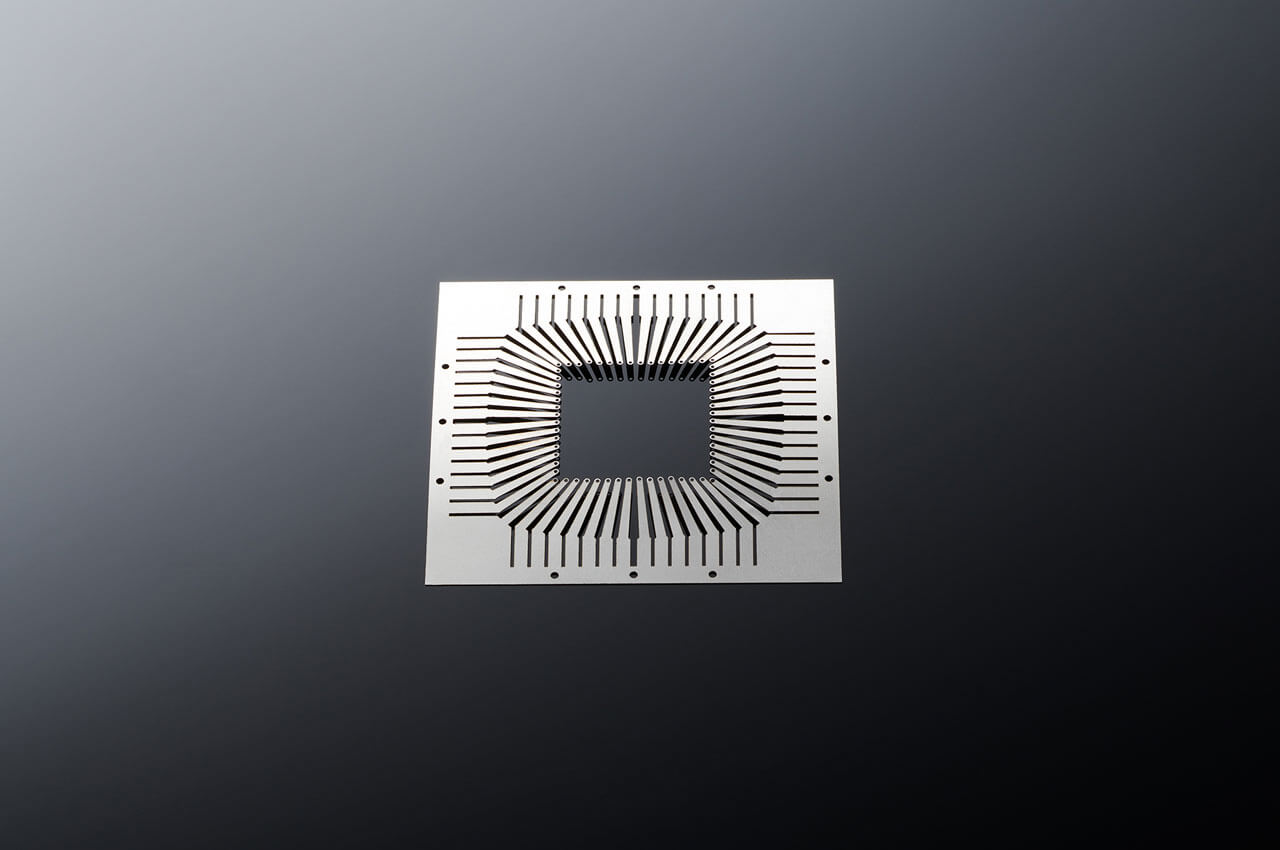

In the product spectrum of power electronics, we manufacture individual components for power electronic assemblies such as motor drives, power supplies, power boards and frequency converters, so-called electronic stacks.

In general, power electronics deals with the conversion, control and switching of electrical energy in various electronic components and thus covers an important subarea of electrical engineering. In hybrid and electric vehicles, it forms a central component of drive technology. This includes, among other things, the control of an electric machine or the communication with the vehicle control system. In the field of renewable energies, special magnetic materials are also required, such as those used for generators in wind power plants.