Ceramic, glass and silicon wafers and substrates

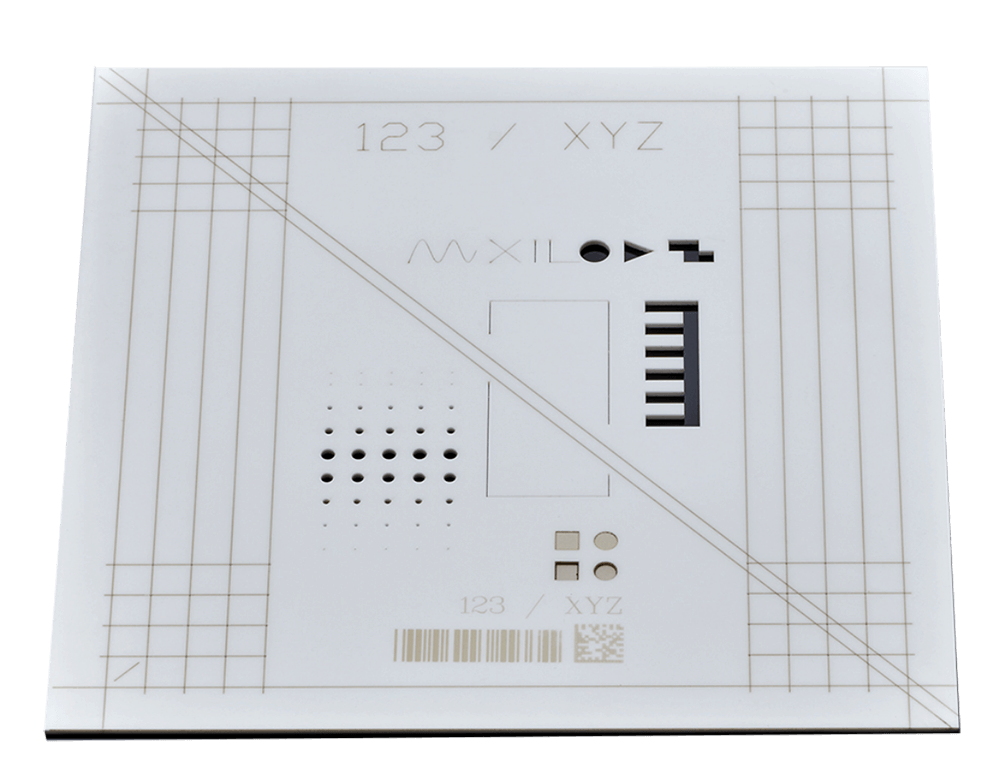

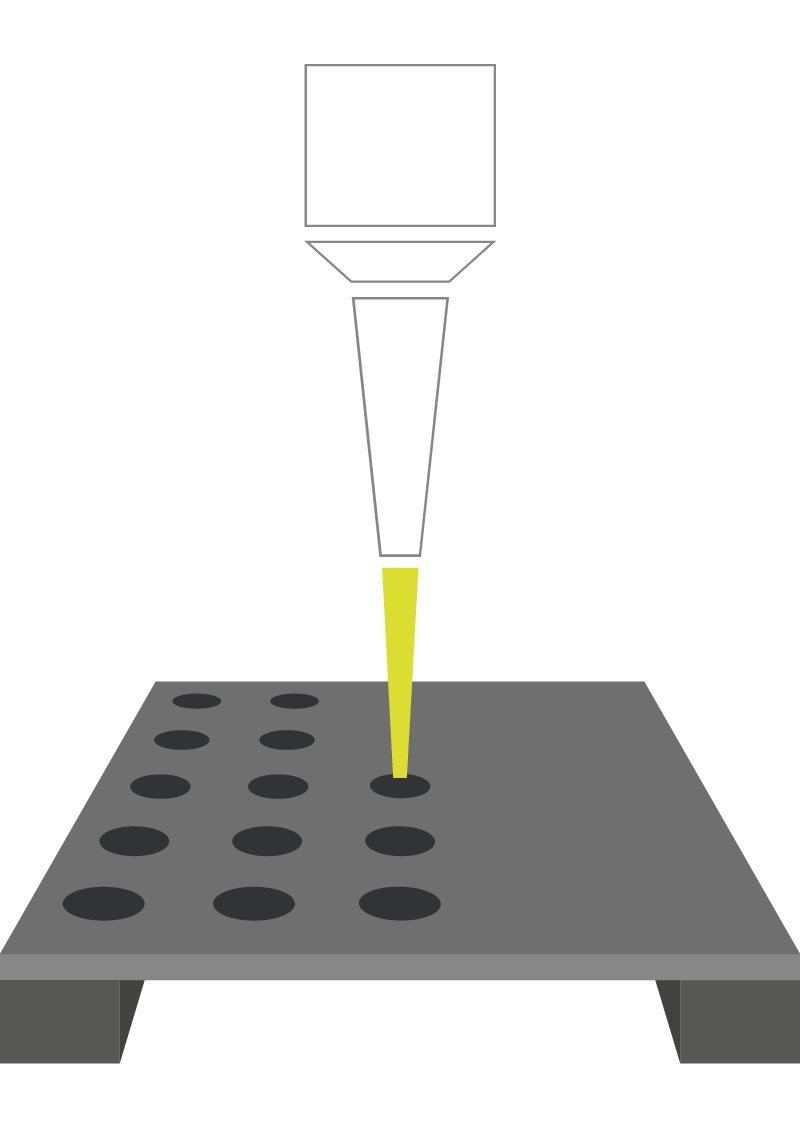

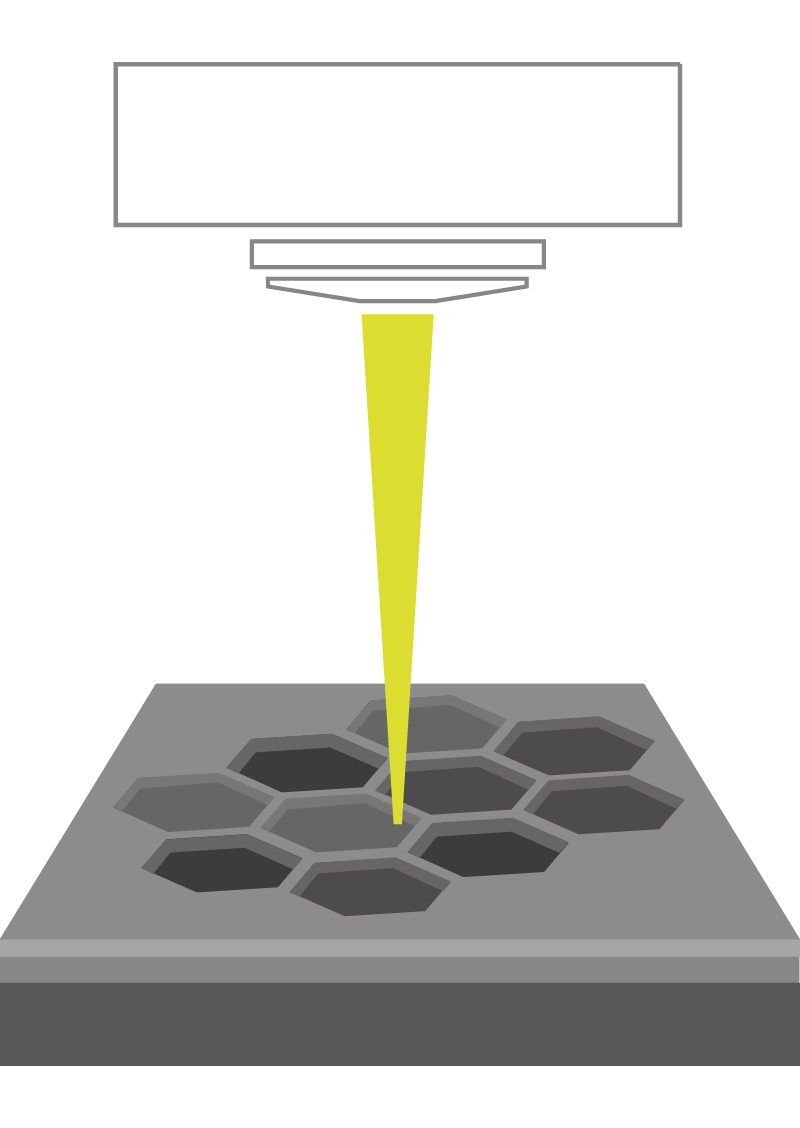

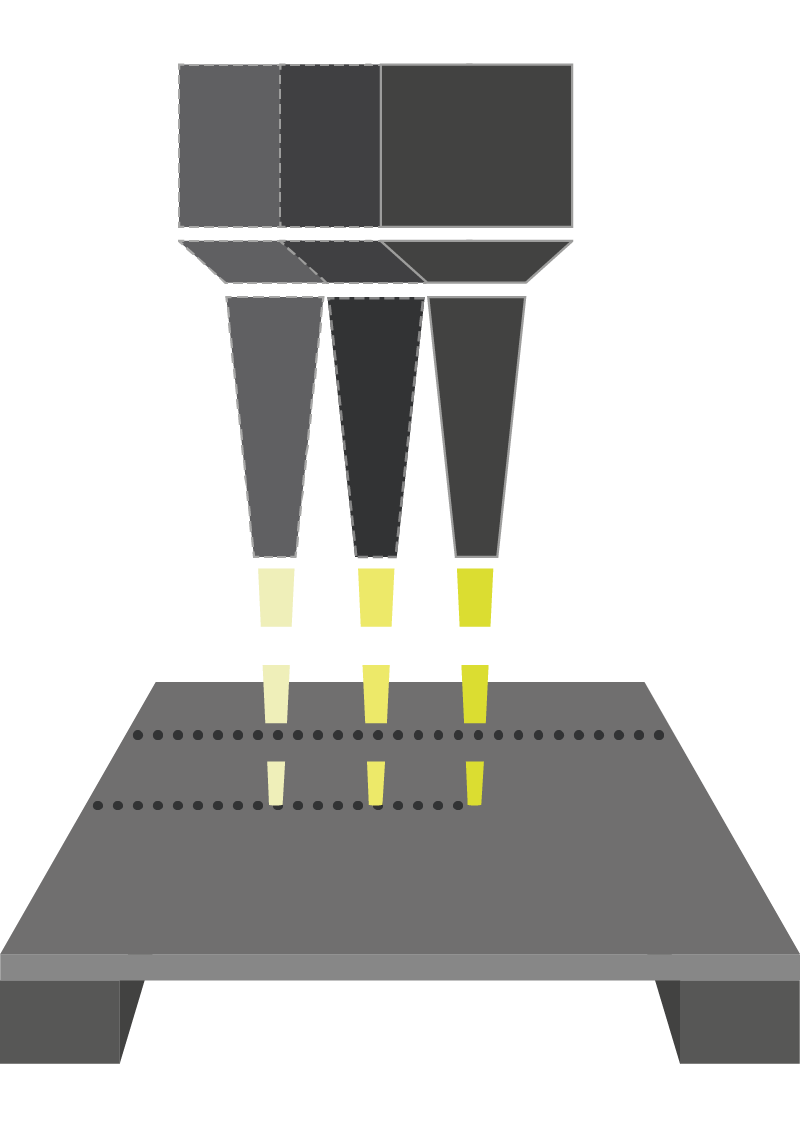

Ceramics, glass, silicon - from these hard-brittle materials in the form of wafers or panels we manufacture filigree precision components such as customised useful substrates, moulded parts, spacers, housings and much more. In the context of microsystem and hybrid electronics, so-called thick-film or thin-film substrates serve as circuit carriers for electronic components such as resistors or integrated circuits (IC). Similar to plastic circuit boards made of FR3 or FR4 material, the substrate can be manufactured using multilayer technology or the individual conductor tracks can be printed in multiple layers. For wafers made of either mono- or polycrystalline silicon as blanks from the semiconductor or optics industry or panels made of high-performance ceramics and technical glasses, we offer not only laser processing but also mechanical dicing.

-

Alumina (Al2O3)

Material Properties

- medium thermal conductivities (20 to 30 W/mK)

- very good electrical insulation (1 x 1014 to 1 x 1015 Ωcm).

- flexural strength (800 MPa), high compressive strength (2 to 4 GPa)

- resistant to thermal shock

- chemically resistant

- bioinert and compatible with foodstuffs

- max. application temp. between 1000 to 1500 °C (without mechanical load).

- surface as-fired: Ra 0.2-0.8 μm suitable for thick-film coating (DS)

- surface as-fired: Ra < 0.1 μm suitable for thin films (DF)

- available as dense and porous material

Manufacturer Selection

- CeramTec

- CoorsTek

- Kerafol

- Kyocera

- Maruwa

Dimensions (Selection)

Dimensions: 115 x 115/ 165 x 115/ 190 x 138 mm

Thickness: 0.12 - 3.0 mm (+/- 10%)

Deflection from thickness 0.5 mm 0.2 - 0.3% of the longest side -

Aluminum nitride (AlN)

Material Properties

- very high thermal conductivity (170 - 230 W/mK)

- good electrical insulation (1 x 105 to 1 x 109 Ωcm).

- flexural strength (300 to 400 MPa), compressive strength > 2 GPa

- very good thermal shock resistance

- chem. resistance: not resistant to caustic soda; inert to melting of III-V compounds; less suitable for applications at temperatures above 1,000°C in water- or oxygen-containing

- oxygen environment or under mechanical stress with simultaneous wetting by water.

- manufacturing process: hot-pressed, dry-pressed, film-cast

Manufacturer Selection

- CeramTec

- CoorsTek

- QSIL

- Maruwa

Dimensions (Selection)

Dimensions: 114 x 114 / 150 x 140 / 138 x 190 mm

Thickness: 0.25 - 5.0 mm -

Zirconia (ZrO2)

Material Properties

- low thermal conductivity (1.5 to 3 W/mK)

- good electrical insulation, oxygen ion conductive

- high flexural strength (> 1 GPa) and fracture resistance

- very high compressive strength (> 4.7 GPa)

- very good tribological properties

- chemically resistant

- fatigue resistant due to phase transformation hardening

- bioinert and compatible with foodstuffs

- max. operating temperature between 600 and 1100 °C

- also available as porous sintered base with good flatness and purity

Manufacturer Selection

- CeramTec

- CoorsTek

- Kerafol, Maruwa

Dimensions (Selection)

Dimensions: 50 x 50 / 100 x 100 / 150 x 150 mm

Thickness: 0.15 - 0.5 mm (+/- 10%) -

Silicon carbide (SiC)

Material Properties

- very high thermal conductivity (120 - 200 W/mK)

- very high hardness

- corrosion and wear resistant

- good tribological properties

- resistant to thermal shock

- max. operating temperature between 1350 and 1600 °C

- Manufacturing process: directly sintered, recrystallised, CVD ( high purity)

Manufacturer Selection

- CoorsTek

- QSIL

- Kyocera Fineceramics

- SiCeram

- CeramTec

- Fraunhofer IKTS

Dimensions (Selection)

Dimensions: 150 x 150 / 115 x 115 mm

Thickness: 2.0 - 6.0 mm -

Silicon nitride (Si3N4)

Material Properties

- medium thermal conductivity

- high compressive strength (3 GPa)

- good fracture and crack toughness (7 MPa√m)

- good tribological properties

- resistant to thermal changes, thermal shock and high temperatures

- chemically resistant

Manufacturer Selection

- CeramTec

- Kyocera Fineceramics

- Kyocera

- SiCeram

- QSIL

- CoorsTek

- Fraunhofer IKTS

Dimensions (Selection)

Dimensions: Ø 650 mm bis 700 x 450 mm

Thickness: 1.0 - 5.0 mm -

Glass ceramic / Glass

Material Properties

LTCC (Low-Temperature-Cofired-Ceramic):

- unsintered (mixture of glass, ceramic and organic solvent), flexible

- sintering already at 900 °C, good for co-firing with metallic components

- suitable for HF-application

- Thermal conductivity (typ. 2 to 3 W/mK)

- max. application temperature only a few 100 °C

Glass:

- thermal conductivity (0.6 - 1.4 W/mK)

- electr. insulation (1010 to 1014 Ωm)

- max. operating temp. depends on glass system (100 °C to over 1000 °C)

- thermal shock resistance depends on glass system

- provided with filter/protective layers on one/ both sides

Manufacturer Selection

- AGC Asahi Glass

- CeramTec

- Corning

- DuPont

- Kerafol

- Plan Optik

- Saint Gobain

- Schott AG

Dimensions (Selection)

Dimensions LTCC: up to 152.4 x 152 mm

Thickness LTCC: 127 - 254 µm (unsintered)Dimensions Glass: Ø 50.8 / 100 mm to 1150 x 850 mm

Thickness Glass: 250 / 430 / 550 / 650 µm -

Silicon (Si)

Material Properties

- thermal conductivity 150 W/mK

- electr. insulation (1 x 10 - 6 to 50 Ωm)

- typ. operating temp. between -40 and 90 °C

- can be provided with filter/protective layers on one or both sides

- chem. resistance: little reactive, at very high temperatures influence of various gases transformations possible

Manufacturer Selection

- Hemlock Semiconductor Group

- Wacker Chemie AG

- Siltronic AG

- PV Crystalox Solar Silicon GmbH

Dimensions (Selection)

Dimensions: Ø 50.8 / 76.2 / 100 / 150 / 200 / 300 mm

Thickness: 0.12 - 3.0 mm

Thermal management in PCBs

Conductive tracks are electrically conductive connections of electronic components on printed circuit boards and integrated circuits. To prevent short circuits or high leakage currents from occurring during current and voltage supply and signal transmission, the conductor paths must be electrically well insulated from each other.

Printed circuit boards or circuit carriers made of glass, ceramics, silicon are ideally suited as heat sinks, as they have an electrically insulating and thermally conductive effect at the same time. Low Temperature Cofired Ceramics, also known as LTCC ceramics, is a technology for manufacturing multilayer circuits based on sintered ceramic carriers in electronics.

Ceramic substrates and more: specialised in special materials

Our special expertise is in the procurement and processing of special materials: from aluminium oxide and zirconium oxide to LTCC and glass foils, aluminium nitride, silicon nitride, silicon carbide and mono- or polycrystalline silicon. The following technologies can be used here:

More info about our materials

The specific data sheets of the individual materials are available on request. The material listing is only a current selection without any claim to completeness. Do you have special requirements? We will be happy to advise you personally on your questions regarding our available materials and services.