Plastics variety for your application

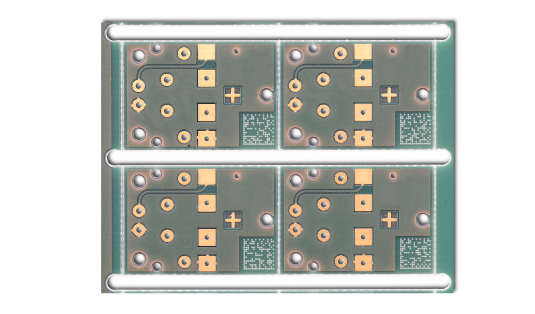

Plastics offer the ideal conditions for use in electronic devices and are therefore decisive for electronics and electrical engineering. As printed circuit boards or circuit boards, plastics act as carriers for electronic components and metallic conductors. In this form, they can be found in almost every electronic device. We process glass-fibre reinforced epoxy circuit boards such as FR3, FR4, FR5 and flexible circuit boards made of polyimide.

More info about our materials

The specific data sheets of the individual materials are available on request. The material listing is only a current selection without any claim to completeness. Do you have special requirements? We will be happy to advise you personally on your questions regarding our available materials and services.