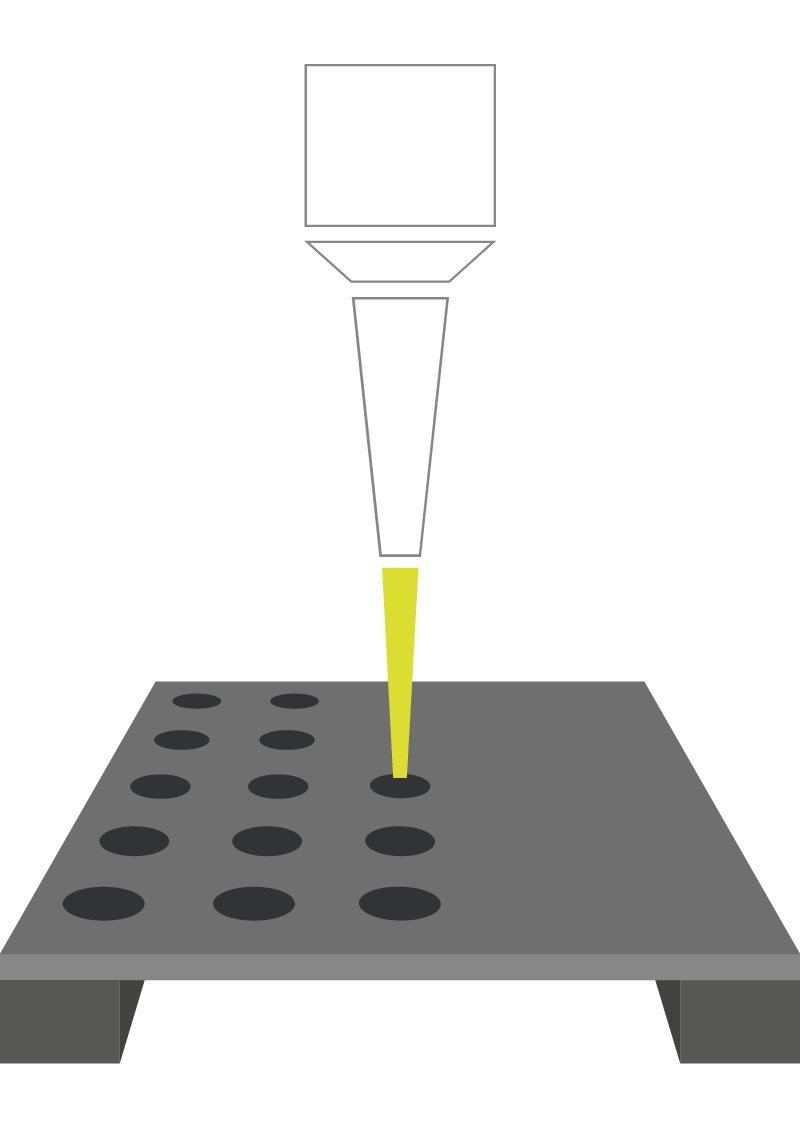

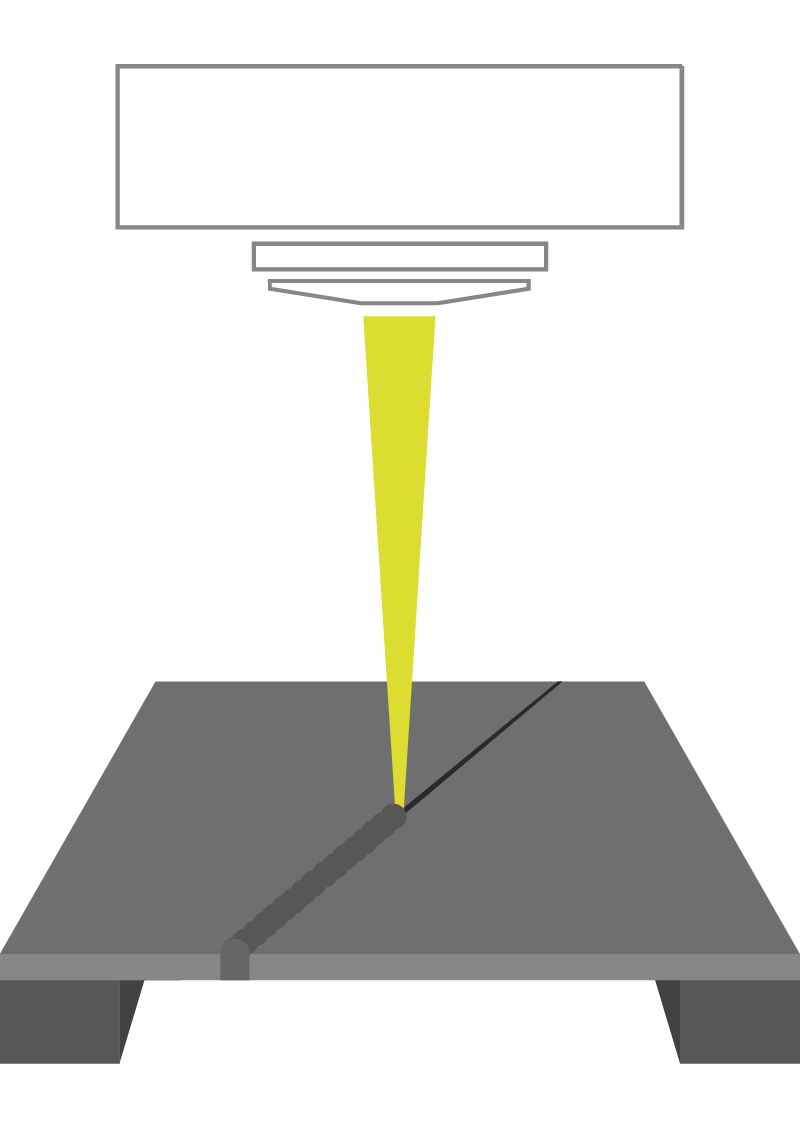

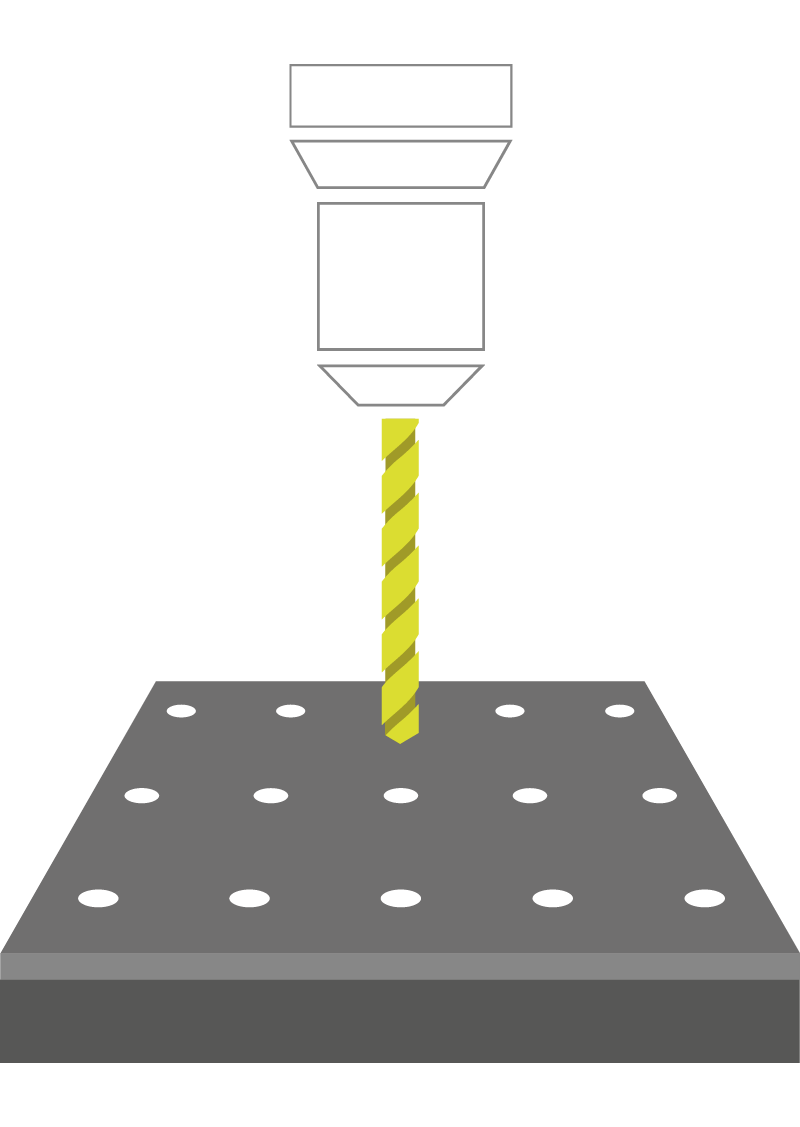

Laser cutting of ferrous metals

Due to its many different alloys, iron is probably the most important metal. In particular, steel, iron with a maximum of 2% carbon content and its low-alloy or high-alloy steel grades have the greatest industrial distribution. High-purity stainless steels with alloying components such as chromium, nickel, titanium, tungsten and molybdenum are made to be corrosion-resistant or spring-hard. We have an enormous number of these special alloys in stock and they can be processed excellently by our laser technology according to your specifications.

More info about our materials

The specific data sheets of the individual materials are available on request. The material listing is only a current selection without any claim to completeness. Do you have special requirements? We will be happy to advise you personally on your questions regarding our available materials and services.