Laser cutting of non-ferrous metals

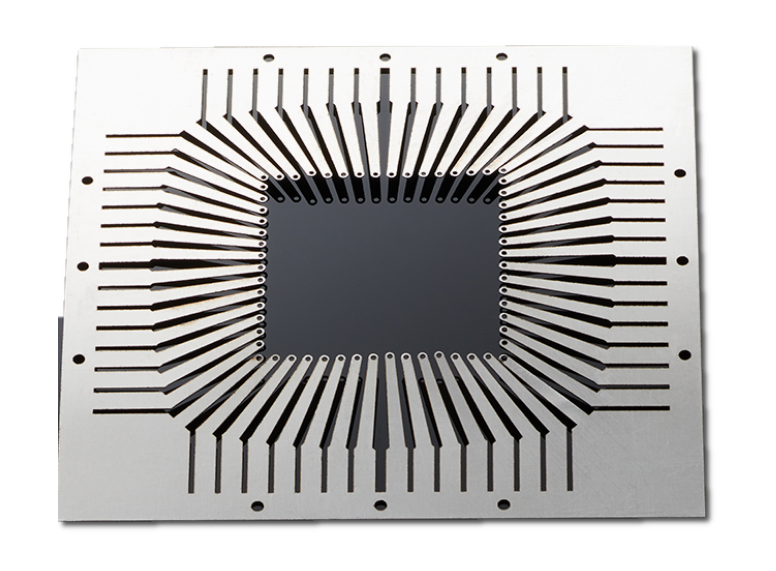

Due to their high electrical conductivity and good corrosion and thermal conductivity, non-ferrous metals have the ideal prerequisites for the production of electrodes, busbars and leadframes as well as for springs, plug contacts or cell sheets. Our special expertise lies in the procurement and processing of special materials. Non-ferrous metals such as copper, nickel, bronze or nickel silver are ideal for laser cutting and laser welding.

More info about our materials

The specific data sheets of the individual materials are available on request. The material listing is only a current selection without any claim to completeness. Do you have special requirements? We will be happy to advise you personally on your questions regarding our available materials and services.