Technical Details

The advantages of laser cutting:

- suitable for different materials

- clean cut edges, hardly any burr formation

- fast, precise and efficient

- less to no post-processing necessary

- flexible processing methods

- lower manufacturing costs without tooling costs compared to punching

- large variety of materials compared to etching

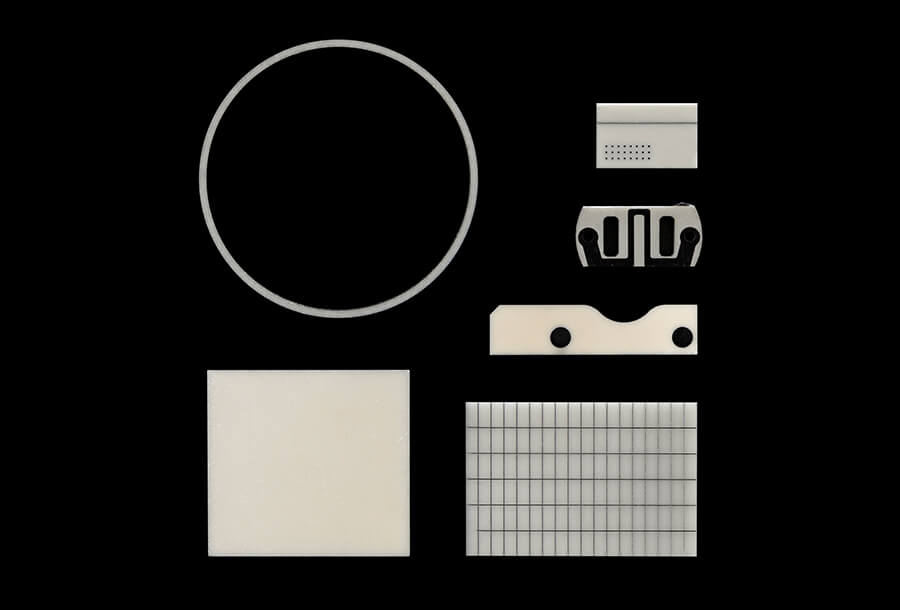

Our three laser cutting processes

Customers from the fields of hybrid and electronics manufacturing (EMS), precision mechanical equipment and apparatus engineering, medical and aerospace technology value our expertise from over 25 years of work experience for laser precision machining. The following three methods are used:

-

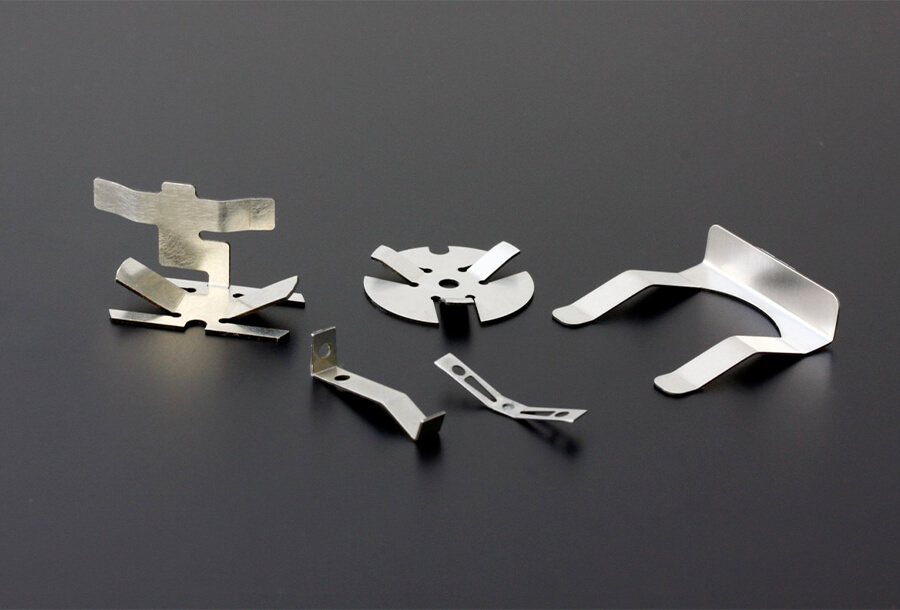

Laser Fusion Cutting

In this non-contact cutting process, as the name suggests, the material is melted with the aid of a focused laser beam. An inert cutting gas shields the processing point from oxidation and thus prevents an exothermic reaction. This cutting process operates at a lower feed rate and thus minimizes the thermal load on the workpiece. As a result, metals can be cut with virtually no distortion or stress. The cut edge is smooth, has no oxidation residues (scale) and forms a neat edge even without finishing.

-

Laser Flame Cutting

Laser flame cutting is mainly used for cutting ferrous materials. A reactive cutting gas, usually oxygen, drives the molten material out of the kerf of the laser beam. The laser cutting process is additionally promoted by the process gas. An exothermic reaction occurs. The feed rate is comparatively high, as is the thermal load on the workpiece. There is a risk of material burn-off or material distortion, and additional post-processing is necessary to remove the oxidation residues (scale).

-

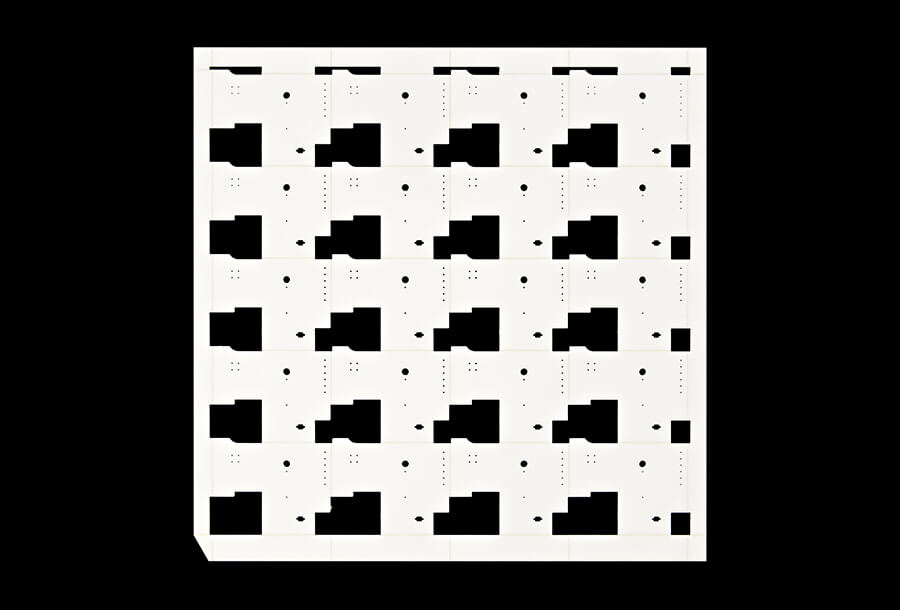

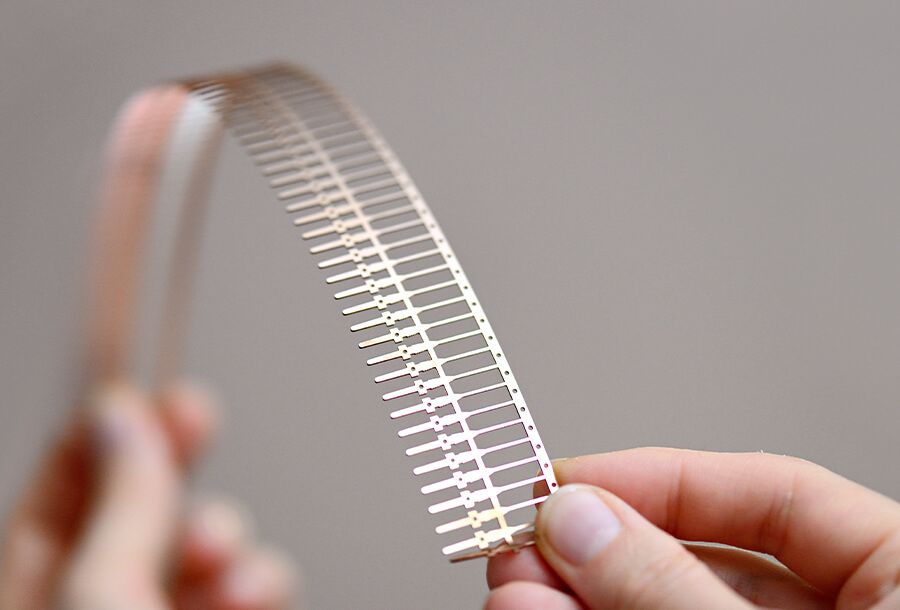

Laser Sublimation Cutting

Laser sublimation cutting is used for thin and delicate materials. The process enables complicated contours, high accuracy and high-quality cut edges with very low burr and roughness. The laser beam alone vaporizes the material. Thus, there is a direct transition from the solid to the gaseous state, creating a fine kerf through layer-by-layer ablation. A almost cold processing occurs, since the material removal takes place without or with extremely low heat conduction within the workpiece.