Post-processing and testing of your manufactured components

After turning/milling, the workpieces are deburred and cleaned. All sharp workpiece edges are broken by vibratory grinding or glass bead blasting and an even surface is created.

Various surface treatments are also possible through cooperation: e.g. passivation, anodising, galvanising, blackening.

We can also test your components by optical and tactile measurements on our 3D coordinate measuring machine.

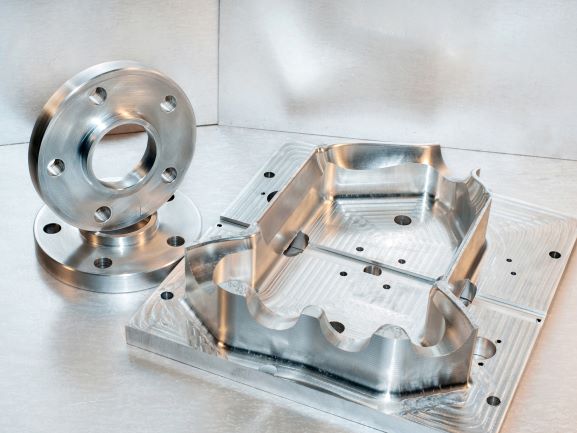

Our application diversity

Discover all technologies now and find out about our available materials. You can see the wide range of possibilities that can be realised in component production under More applications.