Technical possibilities of laser processing of surfaces

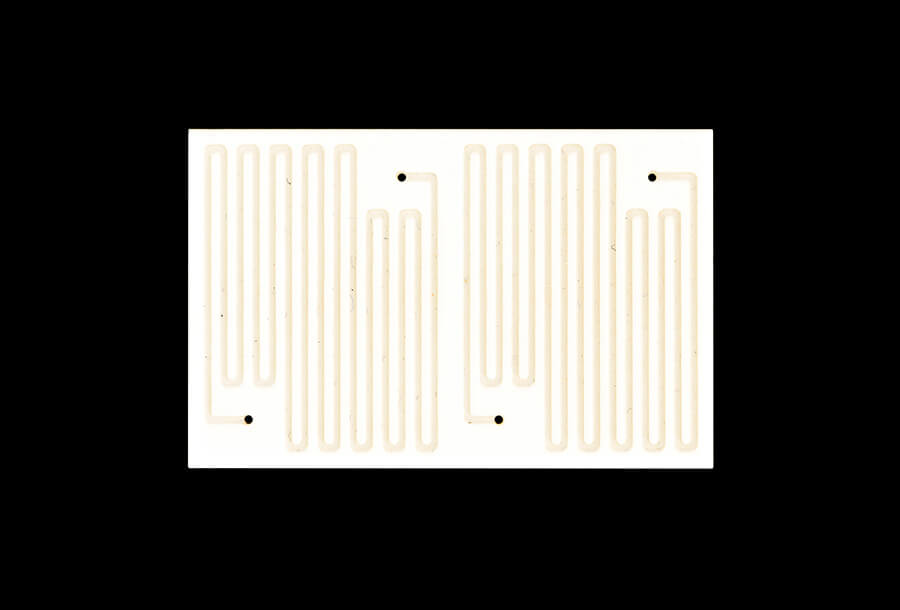

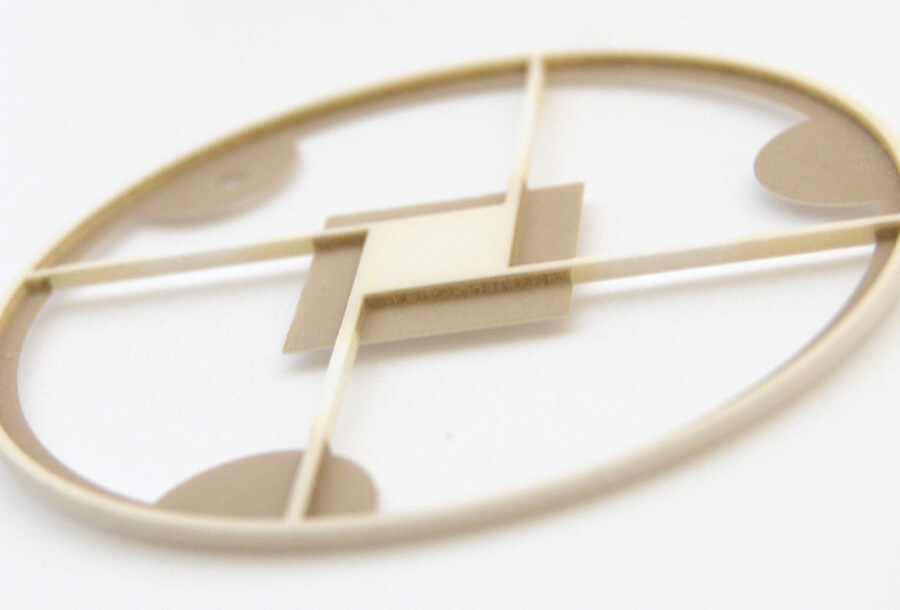

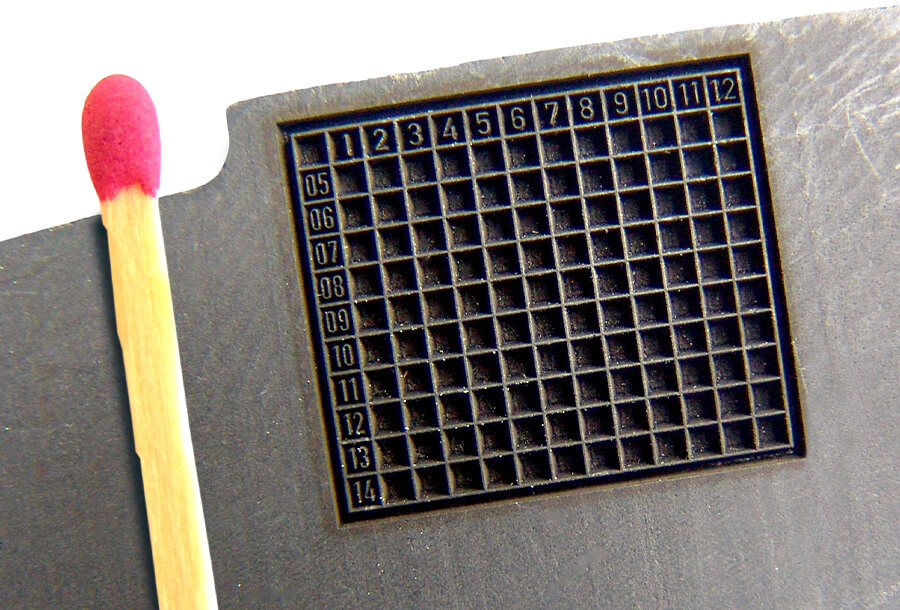

Laser systems for surface structuring, surface modification and micromachining play a crucial role in industrial manufacturing and research. The various processes such as microstructuring, microcutting, ablation, notching and layer ablation enable precise, flexible and diverse processing in the micrometer range. Both deep ablation and surface modifications are realized by ablation, decoating, polishing or roughening. Cavities and blind holes are also implemented by micromachining. A special technique used in this process are ultrashort pulse laser sources, which generate extremely short pulses in the pico-/femtosecond range. Our services support you in activating and cleaning surfaces through a wide range of processing.

Manufacturing technology for different materials

Whether thin-film wafer or thick-film substrate: surface processing by means of laser structuring is suitable for a wide range of different materials. These include metals as well as non-metals and especially hard-brittle materials. Thanks to precise manufacturing technology, the possibilities for processing the following materials are virtually unlimited:

- aluminum oxide (Al2O3, sapphire)

- aluminum nitride (AlN)

- silicon (Si) and silicon nitride (Si3N4)

- sintered silicon carbide (SSiC)

- recrystallized silicon carbide (RSiC)

- glass (-ceramic), quartz

- plastic printed circuit boards made of FR3/FR4/ FR5 (PCB)

- ceramic circuit boards or multilayer (LTCC)

Application areas of laser technology

The very high light intensities achieved in micromachining with ultrashort pulse lasers enable the processing of materials where mechanical processing or other laser technologies reach their limits. However, the advantage of laser processing also lies in the flexibility with which any shape can be produced quickly, precisely and economically.

With the help of clamping devices, so-called chucks, or suction devices with negative pressure, the ultrashort pulse laser cuts materials cleanly without damaging them. Ceramics, glasses and metals are drilled, structured and cut without thermal damage to the material. This opens up new possibilities in electronics, mechanics, medical technology and microfluidics. The versatile manufacturing technology is ideal for useful and network substrates and other thick film hybrids. We support you in the fabrication of:

- heaters,

- conductors,

- masks,

- apertures,

- stencils,

- circuit carriers,

- and microreactors.

Laser processing allows surfaces in the micrometer range to be processed particularly efficiently and precisely. Particularly when using ultrashort pulse lasers, residue-free material removal is feasible, especially when materials are subsequently to be coated - for example, in metallization. For this purpose, no material residues must adhere to the substrates.

Discover our wide range of services

Our large portfolio of machining technologies enables us to produce fast, precise and individual components according to your specifications - from laser drilling and wafer dicing to precision manufacturing of drawing parts.