The smartphone is firmly anchored in our everyday lives and makes them easier in many situations: It allows us to quickly check when the next train is leaving, exchange information with others online in networks, share pictures or videos with family or friends, or navigate to the next vacation destination. Basically, it combines the functions of a classic cell phone with those of a small computer - only in a smaller format that fits in a pants pocket.

The smartphone is just one example of many that accompany us in everyday life and combine a large number of tiny components in their complex interior. One example is the W-LAN antenna in the smartphone. This is usually made of nickel-zinc ferrite, depending on the frequency range, and is installed as a ferrite core.

What are ferrite cores?

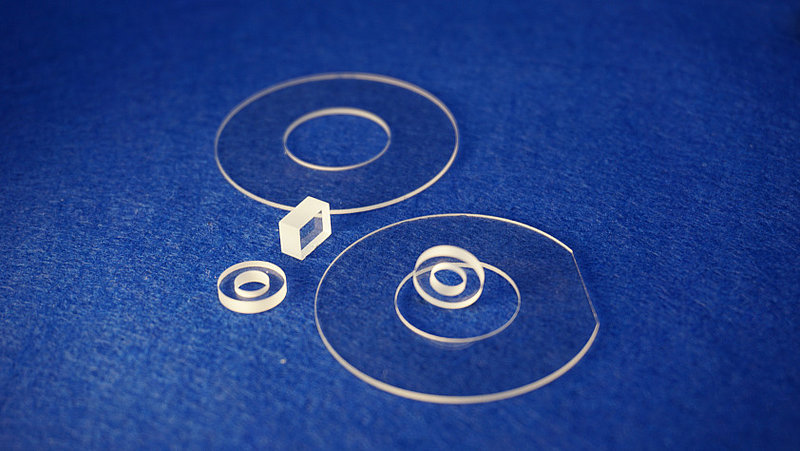

Ferrite cores belong to the functional ceramics based on iron oxide. They are found in every electronic device and are one of the most important components. This is because all electrical devices require an inductance, and this inductance is significantly influenced by ferrite cores in the way they function. Due to their function, they bundle and conduct external magnetic fields and also serve to shield electromagnetic radiation, they are mainly used in power electronics. There they are found in transformers, generators, chokes and coils. Ferrite cores are also found in the field of EMC protection. Here, they dampen high-frequency interference signals in the vicinity of electrical conductors. If a cube were assembled from ferrite plates, its interior would be completely free of magnetic fields in the presence of an external magnetic field - similar to the Faraday cage for the electric field.

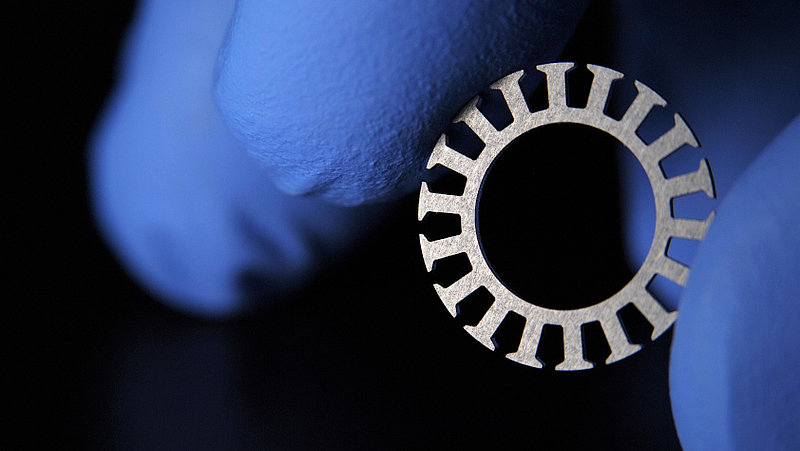

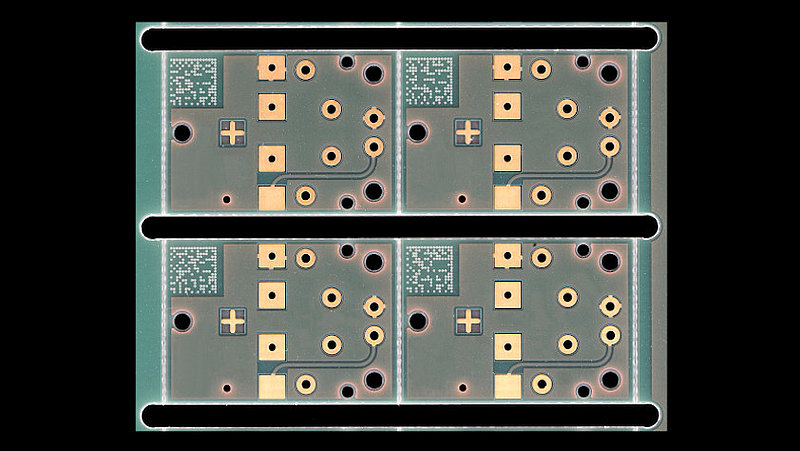

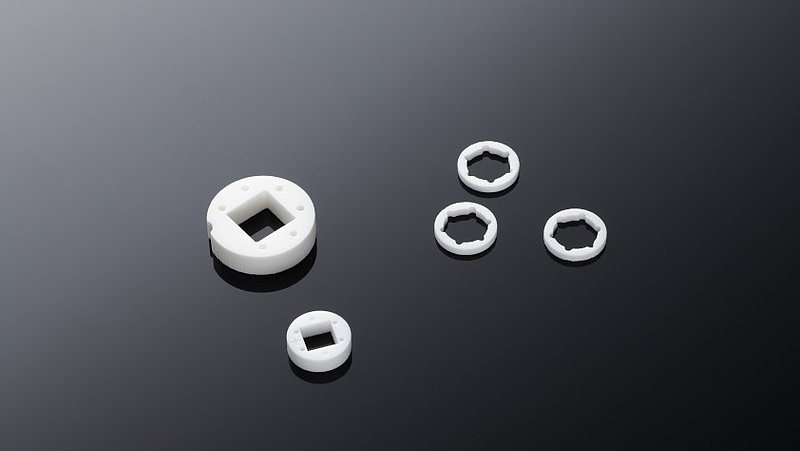

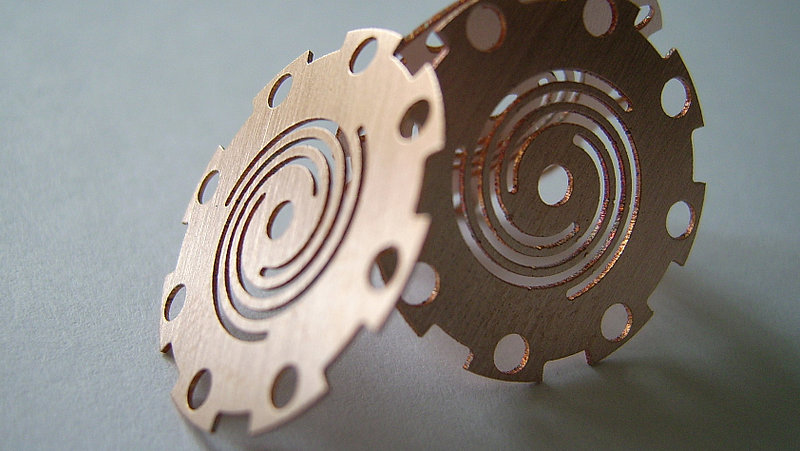

In today's world, with ever more compact devices and significantly more electronics in everyday life, this means that the individual components of electronic devices must be even smaller while maintaining the same functionality. In addition to smartphones, computers and televisions are also among the compact applications where the smallest ferrite cores are used in the control electronics. Here, the installation space for inductors is very limited.

How can high-precision machining and contouring of the smallest ferrite cores be implemented?

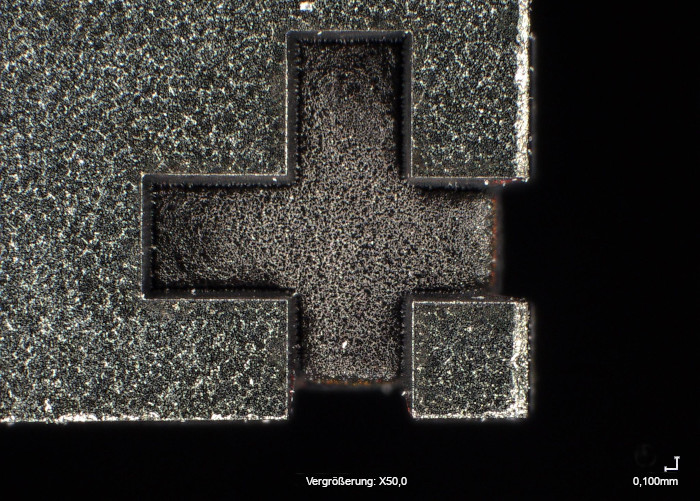

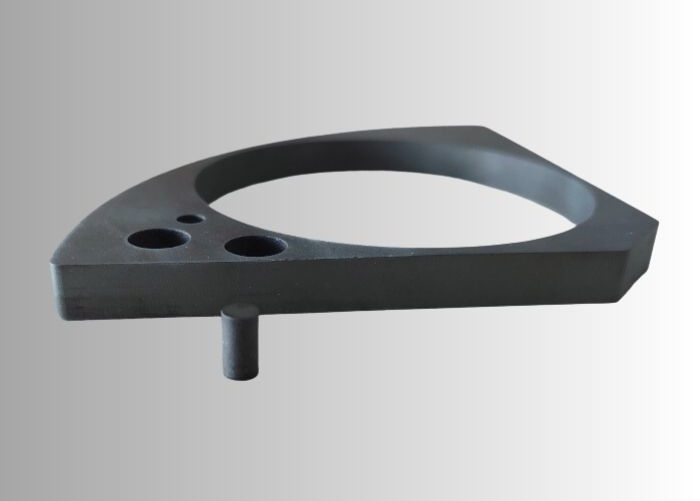

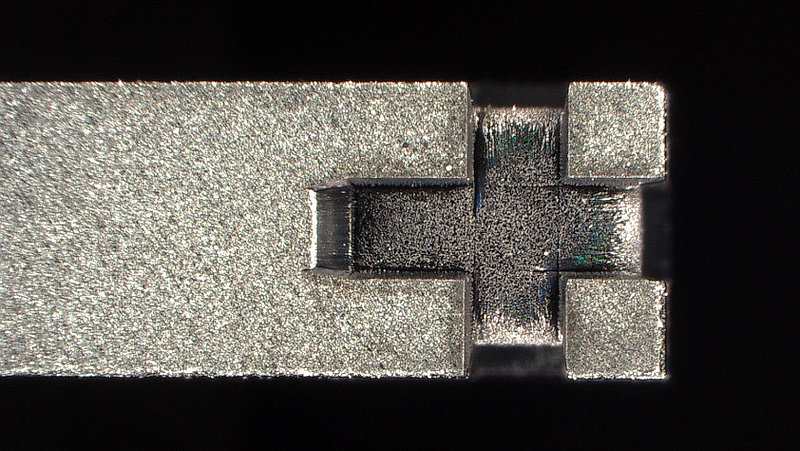

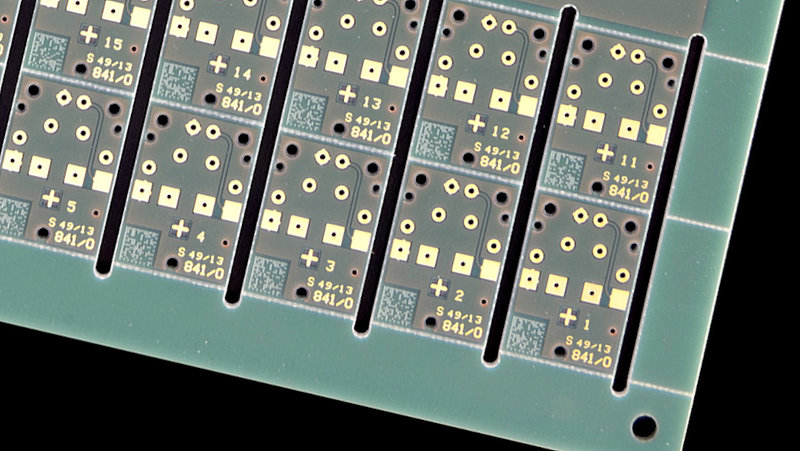

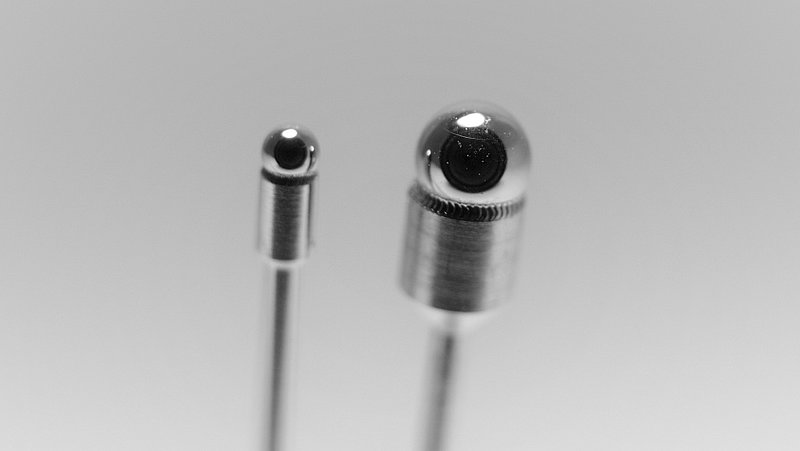

This is where LCP Laser-Cut-Processing GmbH comes into play as an experienced specialist and established application center for high-end micromaterial processing of a wide variety of special materials such as ferrite cores. The company is very well versed in laser precision processing and uses a wide range of processing technologies such as laser cutting, welding, structuring, drilling, scribing and marking. The company also relies on the latest generation of ultrashort pulse (USP) laser technology. Thanks to this innovative laser processing with ultrashort laser pulses, ever smaller components can be processed, all the way to miniaturization with a size of just 3 to 5 millimeters. The special feature: Due to the very short laser pulses at very high pulse frequencies, there is virtually no thermal material damage, as the ablated material evaporates immediately. The so-called "cold ablation" keeps the heat input into the material to a minimum. No burr formation or melt adhesion occurs at the processing points. This greatly reduces the time-consuming post-processing of loosely deposited smear particles. The process of laser ablation in the ultra-short spectrum is very precise and ensures dimensionally stable components with high design flexibility. It also offers extremely high reproducibility and thus reliability in the quality of high volumes. In terms of surface structuring, UPK laser ablation offers a wide range of possibilities: from intact color change to defined microstructure changes (including roughness values) to extreme depth ablation of several millimeters.

![[Translate to English:] LCP's sporting commitment to handball](/fileadmin/_processed_/5/7/csm_handball_engagement_842x474_a29dbbab0e.jpg)

![[Translate to English:] Summer tour: Wolfgang Tiefensee visits LCP](/fileadmin/_processed_/f/7/csm_Besuch_Tiefensee_2022_Balkon_842_3ce801ac88.jpg)

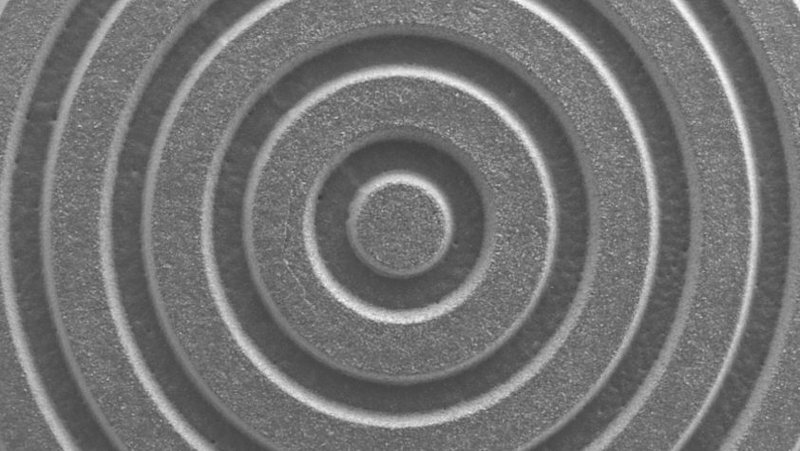

![[Translate to English:] Silizium Wafer](/fileadmin/_processed_/4/5/csm_silizium_wafer_842_022e209b94.jpg)

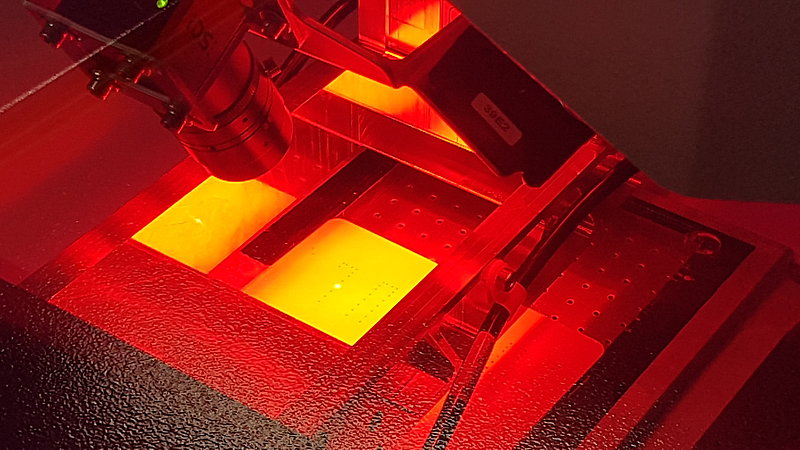

![[Translate to English:] USP-SLS](/fileadmin/_processed_/6/0/csm_UKP-SLS_905ac12200.jpg)