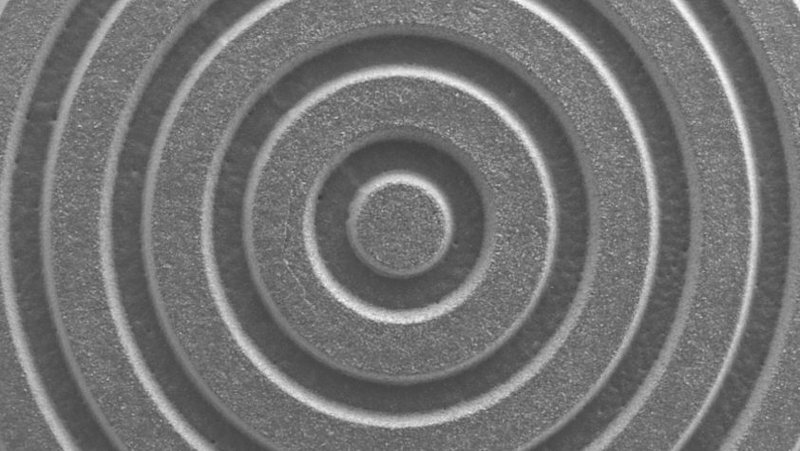

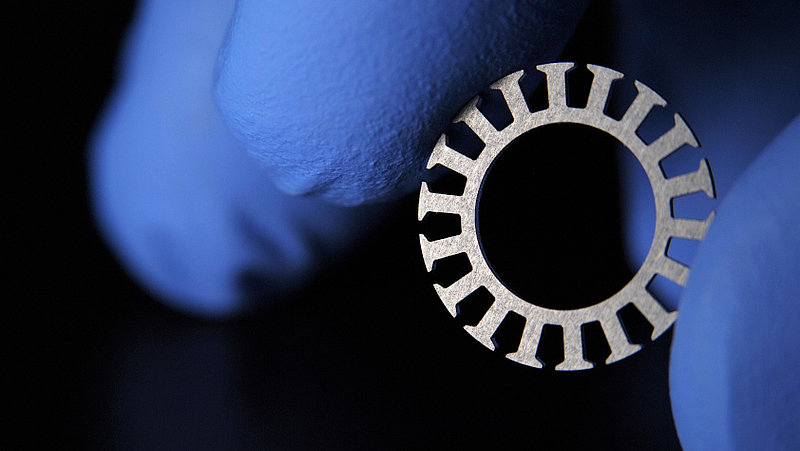

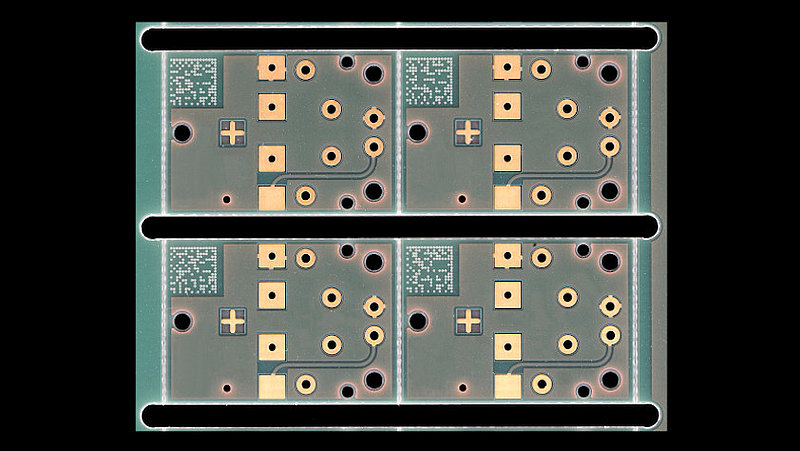

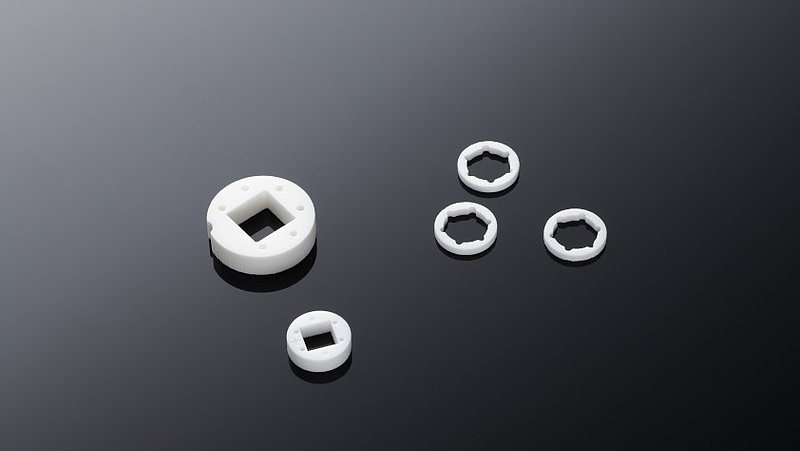

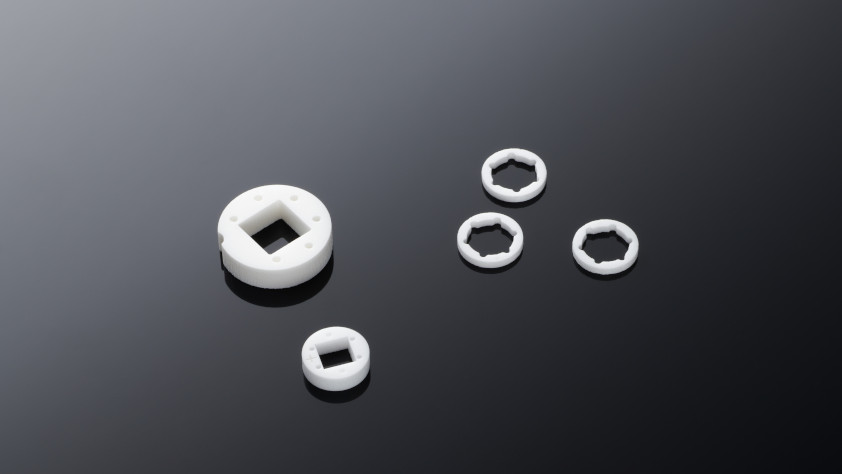

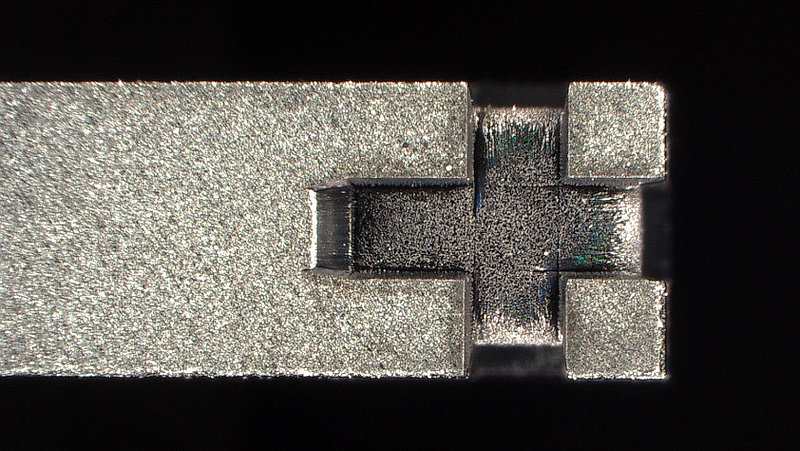

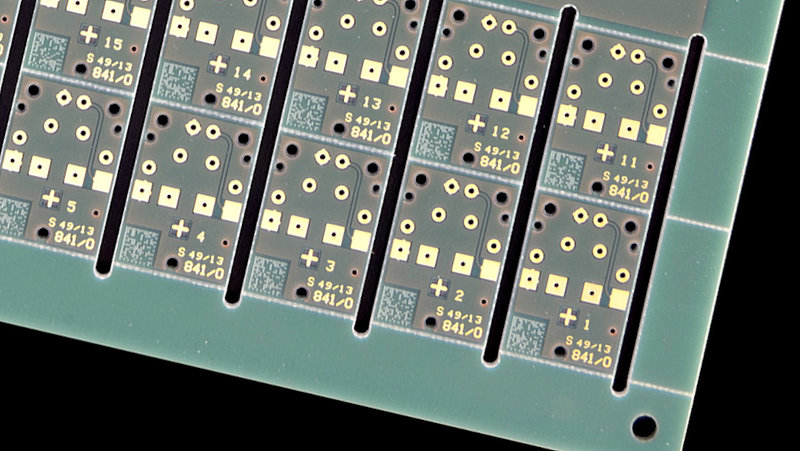

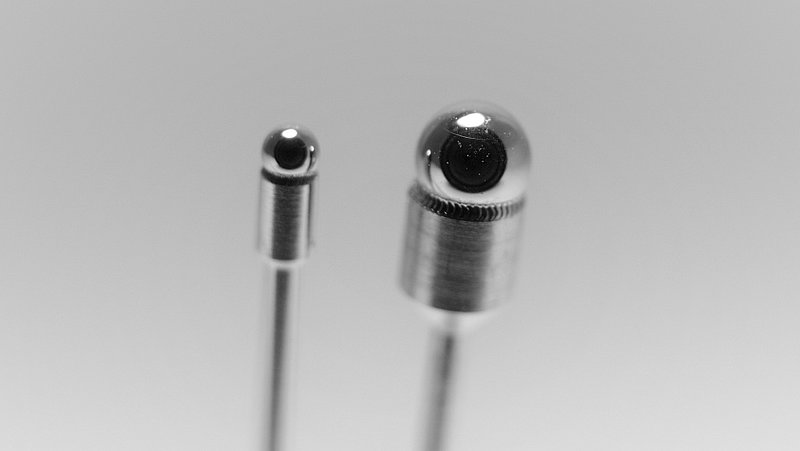

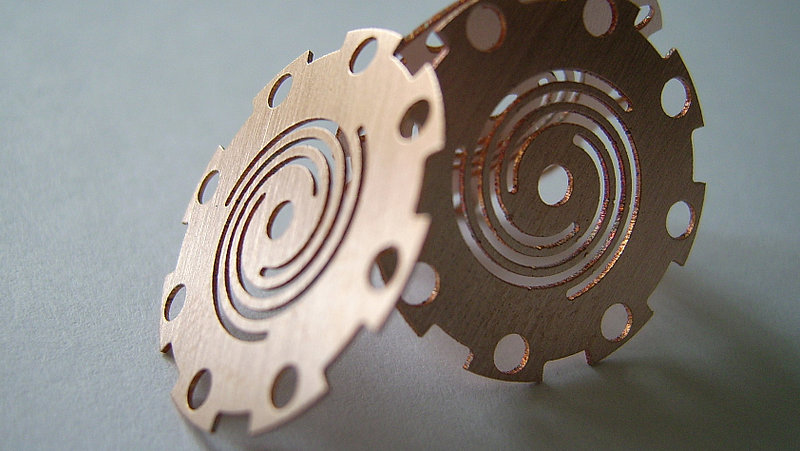

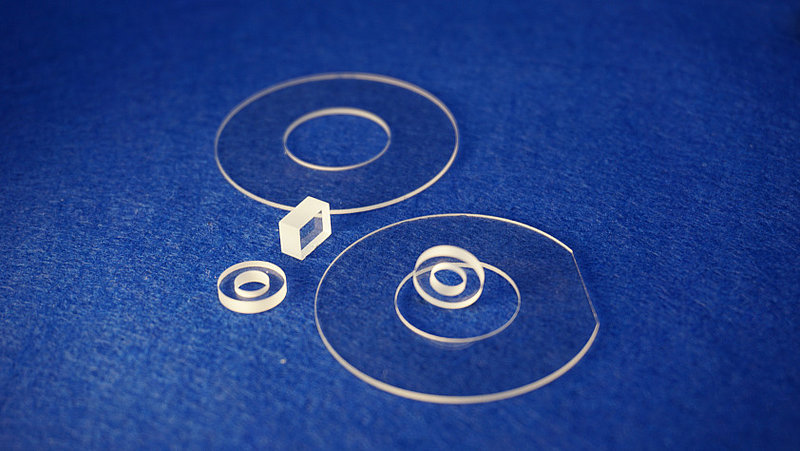

Not only since Industry 4.0 has the demand for sensor systems for condition analysis and monitoring grown strongly. In particular, reliable pressure monitoring in high-temperature applications under harsh environmental conditions represents a major challenge. These requirements can usually only be met by relying on the properties of technical ceramic materials such as aluminium oxide (purity: 96%-99%), aluminium nitride as well as silicon nitride or silicon carbide when constructing the sensor housing (package) in addition to the actual silicon membrane and the steel housing with glass-to-metal feedthrough. The challenges in the production of these ceramic carriers, sensor bases, bond plates or spacer rings, mostly suitable for all types of TO (Transistor Outline), TO bases and TO caps, are, among other things, the extreme layout specifications, which are particularly in the web width ratio or aspect ratio.

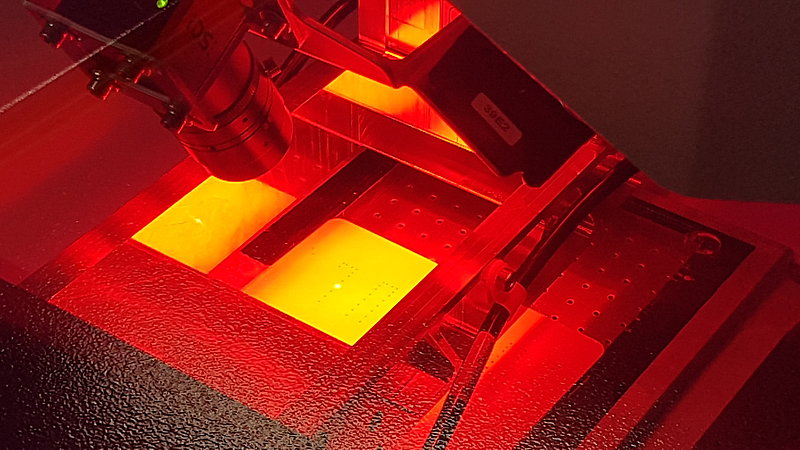

At LCP Laser-Cut-Processing GmbH, we can precisely process densely sintered substrates thanks to economical laser processes and thus produce filigree ceramic parts with web widths of less than the material thickness as well as holes/drillings with an aspect ratio of 5:1 at a component height of up to 3.0 mm. Mechanical, thermal and electrochemical processes are used to deburr and clean the miniature components.

You too can benefit from our innovative laser technology and our know-how from over 25 years of experience.

![[Translate to English:] LCP's sporting commitment to handball](/fileadmin/_processed_/5/7/csm_handball_engagement_842x474_a29dbbab0e.jpg)

![[Translate to English:] Summer tour: Wolfgang Tiefensee visits LCP](/fileadmin/_processed_/f/7/csm_Besuch_Tiefensee_2022_Balkon_842_3ce801ac88.jpg)

![[Translate to English:] Silizium Wafer](/fileadmin/_processed_/4/5/csm_silizium_wafer_842_022e209b94.jpg)

![[Translate to English:] USP-SLS](/fileadmin/_processed_/6/0/csm_UKP-SLS_905ac12200.jpg)